Esikhathini sanamuhla sokuthuthuka okusheshayo kwezobuchwepheshe, izinhlanganisela ze-carbon fibre zizenzela igama emikhakheni eyahlukene ngenxa yokusebenza kwazo okuphezulu. Kusukela kuzinhlelo zokusebenza ezisezingeni eliphezulu ku-aerospace kuya ezidingweni zansuku zonke zezimpahla zemidlalo, izinhlanganisela ze-carbon fibre zibonise amandla amakhulu. Nokho, ukulungiselela high-ukusebenza carbon fibre izinhlanganisela, kusebenze ukwelashwa ofimicu ye-carbonkuyisinyathelo esibalulekile.

Isithombe se-carbon fibre surface electron microscope

I-Carbon fiber, i-fiber material esebenza kahle kakhulu, inezinto eziningi eziphoqayo. Ikakhulukazi yakhiwe ngekhabhoni futhi inokwakheka kwefilamentary emide. Ngokombono wesakhiwo esingaphezulu, ingaphezulu le-carbon fiber libushelelezi futhi linamaqembu ambalwa asebenzayo. Lokhu kungenxa yokuthi ngesikhathi sokulungiswa kwe-carbon fibers, i-carbonization ephezulu yokushisa kanye nezinye izindlela zokwelapha zenza ubuso be-carbon fibers bube nesimo esingenasici. Le ndawo engaphezulu iletha uchungechunge lwezinselelo ekulungiseni izinhlanganisela ze-carbon fibre.

Indawo ebushelelezi yenza isibopho phakathi kwe-carbon fibre ne-matrix material ibe buthaka. Ekulungiseni izinhlanganisela, kunzima ukuthi impahla ye-matrix yakhe isibopho esiqinile ebusweni be-matrix.i-carbon fiber, okuthinta ukusebenza okuphelele kwezinto ezihlanganisiwe. Okwesibili, ukuntuleka kwamaqembu asebenzayo asebenzayo kunciphisa ukusabela kwamakhemikhali phakathi kwe-carbon fibers nezinto ze-matrix. Lokhu kwenza ukuhlangana kobuso phakathi kwalokhu kokubili kuncike kakhulu emiphumeleni engokomzimba, njengokushumeka komshini, njll., okuvamise ukungazinzi ngokwanele futhi okujwayele ukuhlukana uma kubhekene namandla angaphandle.

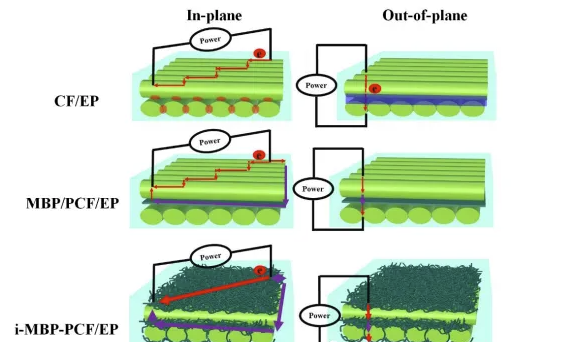

Umdwebo ohleliwe wokuqiniswa kwe-interlayer kwendwangu ye-carbon fiber ngama-carbon nanotubes

Ukuze uxazulule lezi zinkinga, ukwelashwa kokuvula ama-carbon fibers kuba kudingekile. Yenziwe yasebenzaimicu ye-carbonkhombisa izinguquko ezibalulekile ezicini ezimbalwa.

Ukwelashwa kokwenza kusebenze kwandisa ubulukhuni obungaphezulu bemicu ye-carbon. Ngokuxutshwa kwamakhemikhali, ukwelashwa kwe-plasma nezinye izindlela, imigodi emincane nemifantu kungenziwa kugxilwe ebusweni bemicu ye-carbon, okwenza indawo engaphezulu ibe mahhadlahhadla. Le ndawo emangelengele yandisa indawo yokuxhumana phakathi kwe-carbon fiber kanye ne-substrate material, okuthuthukisa isibopho semishini phakathi kwalokhu kokubili. Lapho impahla ye-matrix iboshelwe ku-carbon fiber, ikwazi kangcono ukuzishumeka kulezi zakhiwo ezimahhadlahhadla, yenze isibopho esiqinile.

Ukwelashwa kokwenza kusebenze kungathula inala yamaqembu asebenzayo asebenzayo ebusweni be-carbon fiber. Lawa maqembu asebenzayo angasabela ngokwekhemikhali namaqembu asebenzayo ahambisanayo kokubalulekile kwe-matrix ukuze akhe amabhondi amakhemikhali. Isibonelo, ukwelashwa kwe-oxidation kungethula amaqembu e-hydroxyl, amaqembu e-carboxyl namanye amaqembu asebenzayo ebusweni bemicu ye-carbon, engasabelai-epoxyamaqembu ku-matrix ye-resin nokunye ukwenza amabhondi ahlangene. Amandla alokhu kubopha kwamakhemikhali aphakeme kakhulu kunalawo okubopha ngokomzimba, okuthuthukisa kakhulu amandla okubopha okuhlangana kobuso phakathi kwe-carbon fibre nezinto ze-matrix.

Amandla angaphezulu e-carbon fibre ecushiwe nawo anda kakhulu. Ukwanda kwamandla angaphezulu kwenza kube lula ukuthi i-carbon fibre imanziswe yi-matrix material, ngaleyo ndlela kube lula ukusabalala nokungena kwempahla ye-matrix ebusweni be-carbon fiber. Enqubweni yokulungiselela ama-composites, i-matrix material ingasatshalaliswa ngokulinganayo eduze kwe-carbon fibers ukwakha isakhiwo esiminyene kakhulu. Lokhu akugcini nje ukuthuthukisa izakhiwo zemishini yezinto ezihlanganisiwe, kodwa futhi kuthuthukisa ezinye izakhiwo zayo, njengokumelana nokugqwala nokuzinza kokushisa.

Amafayibha e-carbon acushiwe anezinzuzo eziningi zokulungiselela izinhlanganisela ze-carbon fibre.

Ngokuya ngezici zemishini, amandla okubopha okuhlangana ubuso phakathi kokucushiweimicu ye-carbonfuthi okubalulekile kwe-matrix kuthuthukiswa kakhulu, okwenza izinhlanganisela zikwazi ukudlulisa kangcono izingcindezi uma zingaphansi kwamandla angaphandle. Lokhu kusho ukuthi izakhiwo zemishini zezinhlanganisela ezifana namandla nemodulus zithuthukiswa kakhulu. Isibonelo, emkhakheni we-aerospace, odinga izakhiwo eziphakeme kakhulu zemishini, izingxenye zendiza ezenziwe ngezinhlanganisela ze-carbon fiber ezicushiwe ziyakwazi ukumelana nemithwalo emikhulu yendiza futhi zithuthukise ukuphepha nokuthembeka kwendiza. Emkhakheni wezimpahla zemidlalo, ezifana namafreyimu amabhayisikili, amakilabhu egalofu, njll., izinhlanganisela ze-carbon fibre ezicushiwe zinganikeza amandla angcono nokuqina, kuyilapho kunciphisa isisindo futhi kuthuthukisa umuzwa wabasubathi.

Mayelana nokumelana nokugqwala, ngenxa yokwethulwa kwamaqembu asebenzayo asebenzayo ebusweni bemicu ye-carbon ecushiwe, lawa maqembu asebenzayo angakha ukubopha kwamakhemikhali okuzinzile nokokusebenza kwe-matrix, ngaleyo ndlela kuthuthukise ukumelana nokugqwala kwezinhlanganisela. Kwezinye izimo zemvelo ezinzima, njengemvelo yasolwandle, imboni yamakhemikhali, njll., okucushiweizinhlanganisela ze-carbon fibreingamelana kangcono nokuguguleka kwabezindaba ezonakalisayo futhi andise impilo yesevisi. Lokhu kubaluleke kakhulu kwezinye izinto zokusebenza nezakhiwo ezisetshenziswa ezindaweni ezinokhahlo isikhathi eside.

Mayelana nokuzinza kwe-thermal, ukuhlangana okuhle phakathi kobuso phakathi kwe-activated carbon fibre kanye nokokusebenza kwe-matrix kungathuthukisa ukuzinza kokushisa kwezinhlanganisela. Ngaphansi kwemvelo yokushisa ephezulu, izinhlanganisela zingagcina izakhiwo ezingcono zemishini nokuzinza kwe-dimensional, futhi azijwayele ukuguquguquka kanye nokulimala. Lokhu kwenza izinhlanganisela ze-carbon fibre ecushiwe zibe namathemba okusebenza abanzi ezinhlelweni zokushisa eziphezulu, njengezingxenye zenjini yezimoto nezingxenye zokuphela ezishisayo zenjini yendiza.

Mayelana nokusebenza kokucubungula, amafayibha ekhabhoni acushiwe akhulise umsebenzi ongaphezulu kanye nokuhambisana kangcono nokokusebenza kwe-matrix. Lokhu kwenza kube lula ukuthi impahla ye-matrix ingene futhi yelaphe ebusweni be-carbon fiber ngesikhathi sokulungiswa kwezinto eziyinhlanganisela, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kokucubungula kanye nekhwalithi yomkhiqizo. Ngesikhathi esifanayo, ukuklama kwezinhlanganisela ze-carbon fibre ecushiwe nakho kuyathuthukiswa, okuzivumela ukuthi zenzelwe izinhlelo zokusebenza ezahlukene futhi zihlangabezane nezidingo ezihlukahlukene zobunjiniyela eziyinkimbinkimbi.

Ngakho-ke, ukwelashwa kokwenza kusebenze kweimicu ye-carboniyisixhumanisi esibalulekile ekulungiseleleni izinhlanganisela ze-carbon fibre ezisebenza kahle kakhulu. Ngokwelashwa kokwenza kusebenze, isakhiwo esingaphezulu se-carbon fiber singathuthukiswa ukuze kwandiswe ubuqhwaga obungaphezulu, kwethulwe amaqembu asebenzayo asebenzayo, futhi kuthuthukiswe amandla angaphezulu, ukuze kuthuthukiswe amandla okubopha okuphakathi kobuso phakathi kwe-carbon fiber ne-matrix material, futhi kubekwe isisekelo sokulungiswa kwezinhlanganisela ze-carbon fibre ezinezakhiwo ezinhle kakhulu zemishini, ukumelana nokugqwala, ukuzinza okushisayo nokusebenza kokucubungula. Ngokuqhubeka okuqhubekayo kwesayensi nobuchwepheshe, kukholakala ukuthi ubuchwepheshe be-carbon fiber activation buzoqhubeka nokusungula futhi buthuthuke, bunikeze ukwesekwa okunamandla kokusetshenziswa okubanzi kwezinhlanganisela ze-carbon fiber.

I-Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368(futhi whatsapp)

T: +86 08383990499

Email: grahamjin@jhcomposites.com

Ikheli: NO.398 New Green Road Xinbang Town Songjiang District,Shanghai

Isikhathi sokuthumela: Sep-04-2024