Amathreyi ebhethri ayinhlanganisela ye-Thermoplastic aba ubuchwepheshe obubalulekile emkhakheni wezimoto zamandla amasha. Amathreyi anjalo ahlanganisa izinzuzo eziningi zezinto ze-thermoplastic, okuhlanganisa isisindo esilula, amandla aphakeme, ukumelana nokugqwala, ukuguquguquka kokuklama, kanye nezakhiwo ezinhle kakhulu zemishini. Lezi zakhiwo zibalulekile ekuqinisekiseni ukuqina nokuthembeka kwamathreyi ebhethri. Ngaphezu kwalokho, isistimu yokupholisa ephaketheni lebhethri le-thermoplastic idlala indima ebalulekile ekugcineni ukusebenza kwebhethri, ukwelula impilo yayo, kanye nokuqinisekisa ukusebenza okuphephile. Uhlelo olusebenzayo lokuphatha okushisayo luqinisekisa ukuthi ibhethri igcinwa ngaphakathi kwezinga lokushisa elifunekayo ngaphansi kwazo zonke izimo zokusebenza, ngaleyo ndlela kwandise ukusebenza kahle kwebhethri nokuphepha.

Njengobuchwepheshe obuvumela ukushaja okusheshayo, i-Kautex ibonisa ukuqaliswa kokupholisa kokucwiliswa kwezigaba ezimbili, lapho iseli lokudonsa lisetshenziswa njenge-evaporator kwinqubo yokupholisa. Ukupholisa ukucwiliswa kwezigaba ezimbili kufinyelela izinga eliphezulu kakhulu lokudlulisa ukushisa elingu-3400 W/m^2*K kuyilapho kukhulisa ukufana kwezinga lokushisa ngaphakathi kwephakethe lebhethri ezingeni lokushisa elilungile lebhethri. Ngenxa yalokho, isistimu yokulawula ukushisa kwebhethri ingakwazi ukuphatha ngokuphephile futhi unomphela imithwalo eshisayo ngamanani okushaja angaphezu kuka-6C. Ukusebenza kokupholisa kokupholisa kwezigaba ezimbili zokucwiliswa kungaphinda kuvimbele ngempumelelo ukusakazeka kokushisa ngaphakathi kwegobolondo lebhethri eliyinhlanganisela ye-thermoplastic, kuyilapho ukupholisa okugxiliswa kwezigaba ezimbili okwethulwe kukhipha ukushisa endaweni kufika ku-30°C. Umjikelezo we-thermal uyabuyiseleka emuva, okuvumela ukushisisa kahle kwebhethri ezimeni ezibandayo. Ukuqaliswa kokugeleza kokudlulisa ukushisa okubilayo kuqinisekisa ukudluliswa kokushisa okuphezulu okuqhubekayo ngaphandle kokuwa kwebhamuza le-vapor kanye nokulimala kwe-cavitation okulandelayo.

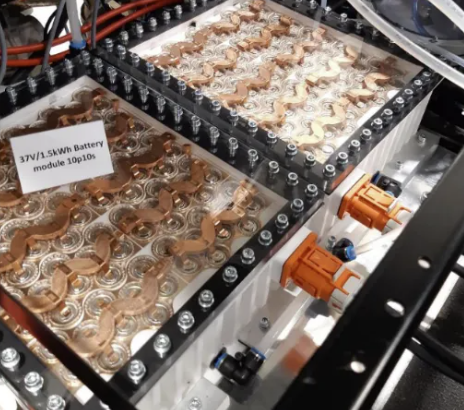

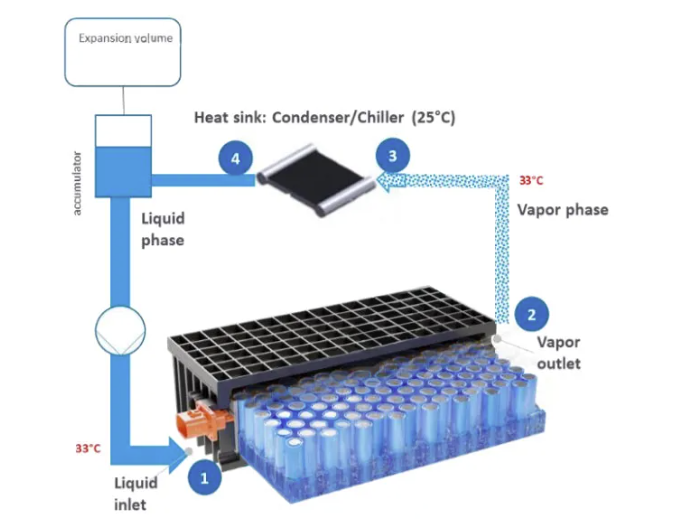

Umfanekiso 1 Izindlu zengxenye ye-Thermoplastic ezinesistimu yokupholisa yezigaba ezimbiliEmcabangweni wokupholisa wokucwiliswa wezigaba ezimbili oqondile we-Kautex, uketshezi luthintana ngokuqondile namaseli ebhethri ngaphakathi kwendlu yebhethri, okulingana ne-evaporator emjikelezweni wesiqandisi. Ukucwiliswa kweseli kukhulisa ukusetshenziswa kwendawo yeseli ekudluliseni ukushisa, kuyilapho ukuhwamuka okuqhubekayo koketshezi, okungukuthi ukushintsha kwesigaba, kuqinisekisa ukufana okuphezulu kwezinga lokushisa. I-schematic iboniswa kuMfanekiso 2.

Umdwebo 2 Umgomo wokusebenza kokupholisa ukucwiliswa kwezigaba ezimbili

Umqondo wokuhlanganisa zonke izingxenye ezidingekayo zokusabalalisa uketshezi ngokuqondile kugobolondo lebhethri le-thermoplastic, elingaqhubeki uthembisa ukuba yindlela eqhubekayo. Uma igobolondo lebhethri nethreyi yebhethri zenziwe ngezinto ezifanayo, zingashiselwa ndawonye ukuze kuqiniswe isakhiwo kuyilapho kususwa isidingo sezinto ezihlanganisayo kanye nokwenza lula inqubo yokugaywa kabusha.

Ucwaningo luye lwabonisa ukuthi indlela yokupholisa yezigaba ezimbili yokucwiliswa isebenzisa isipholile se-SF33 ibonisa amandla aphakeme okukhipha ukushisa ekudluliseni ukushisa kwebhethri. Lolu hlelo lugcine amazinga okushisa ebhethri ku-34-35°C ngaphansi kwazo zonke izimo zokuhlola, okubonisa ukufana okuhle kakhulu kwezinga lokushisa. ama-coolants afana ne-SF33 ahambisana nezinsimbi eziningi, amapulasitiki, nama-elastomers, futhi ngeke alimaze izinto zebhethri le-thermoplastic.

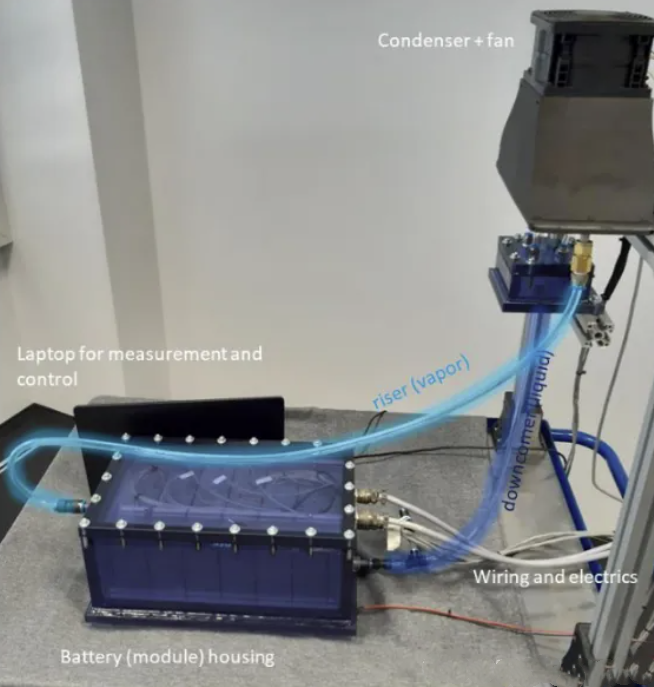

Umfanekiso 3 Isilingo sokulinganisa ukudluliswa kokushisa kwephakethe lebhethri [1]

Ukwengeza, ucwaningo lokuhlola luqhathanise amasu okupholisa ahlukene afana ne-convection yemvelo, i-convection ephoqelelwe, kanye nokupholisa uketshezi nge-SF33 epholile, futhi imiphumela yabonisa ukuthi uhlelo lokupholisa lwezigaba ezimbili lwalusebenza kahle kakhulu ekugcineni izinga lokushisa lamaseli ebhethri.

Sekukonke, isistimu yokupholisa yezigaba ezimbili yokucwiliswa ihlinzeka ngesixazululo sokupholisa ibhethri esisebenza kahle nesifanayo sezimoto zikagesi nezinye izinhlelo zokusebenza ezidinga ukugcinwa kwamandla, okusiza ukuthuthukisa ukuqina nokuphepha kwebhethri.

Isikhathi sokuthumela: Oct-14-2024