Kweli xesha lanamhlanje lenkqubela phambili yetekhnoloji ekhawulezayo, imidibaniso yecarbon fiber izenzela igama kuluhlu olubanzi lweenkalo ngenxa yokusebenza kwayo okuphezulu. Ukususela kwizicelo eziphezulu kwi-aerospace kwiimfuno zemihla ngemihla zeempahla zemidlalo, i-carbon fiber composites ibonise amandla amakhulu. Nangona kunjalo, ukulungiselela i-high-performance carbon fiber composites, kusebenze unyango lweiifayibha zekhabhonilinyathelo elibalulekileyo.

Umfanekiso we-elektroni womphezulu we-carbon fiber

Ifayibha yeCarbon, i-high-performance fiber material, ineempawu ezininzi ezinyanzelisayo. Ubukhulu becala yenziwe ngekhabhoni kwaye inolwakhiwo olude lwefilamentary. Ukusuka kwimbono yesakhiwo somphezulu, umphezulu we-carbon fiber ulula kwaye unamaqela amancinci asebenzayo. Oku kubangelwa ukuba ngexesha lokulungiswa kweefayili zekhabhoni, i-carbonization ephezulu yobushushu kunye nolunye unyango lwenza ukuba umphezulu we-carbon fibers ube ne-inert state. Le propathi engaphezulu izisa uthotho lwemingeni ekulungisweni kweecomposites zecarbon fiber.

Umphezulu ogudileyo wenza ukuba iqhina phakathi kwecarbon fiber kunye ne-matrix ibe buthathaka. Ekulungiseleleni ii-composites, kunzima ukuba izinto ze-matrix zenze ibhondi eyomeleleyo kumphezulu we-matrix.carbon fiber, echaphazela ukusebenza ngokubanzi kwezinto ezidibeneyo. Okwesibini, ukungabikho kwamaqela asebenzayo asebenzayo kunciphisa ukusabela kweekhemikhali phakathi kwe-carbon fibers kunye nezixhobo ze-matrix. Oku kwenza ukuba i-interfacial bonding phakathi kwezi zimbini zixhomekeke kakhulu kwimiphumo yomzimba, njengokufakela oomatshini, njl., ehlala ingazinzile ngokwaneleyo kwaye ilungele ukuhlukana xa iphantsi kwamandla angaphandle.

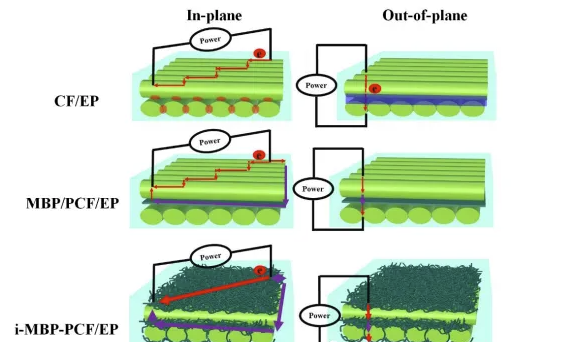

Umzobo weSchematic we-interlayer yokuqinisa ilaphu le-carbon fiber nge-carbon nanotubes

Ukuze kulungiswe ezi ngxaki, unyango olusebenzayo lwe-carbon fibers luba yimfuneko. Yenziwe yasebenzaiifayibha zekhabhonibonisa utshintsho olubalulekileyo kwimiba emininzi.

Unyango olusebenzayo lwandisa uburhabaxa bomphezulu bemicu yekhabhoni. Ngokusebenzisa imichiza ye-oxidation, unyango lweplasma kunye nezinye iindlela, imingxuma emincinci kunye neegrooves zinokufakwa kumphezulu wemicu yekhabhoni, yenze umphezulu ube rhabaxa. Lo mhlaba onqabileyo wandisa indawo yoqhagamshelwano phakathi kwe-carbon fiber kunye ne-substrate material, ephucula ukudibanisa komatshini phakathi kwezi zibini. Xa izinto ze-matrix zibotshelelwe kwifayibha yekhabhoni, ikwazi ngcono ukuzimilisela kwezi zakhiwo zirhabaxa, zenza ibhondi eyomeleleyo.

Unyango olusebenzayo lunokwazisa ubuninzi bamaqela asebenzayo asebenzayo kumphezulu we-carbon fiber. La maqela asebenzayo anokusabela ngamachiza kunye namaqela asebenzayo ahambelanayo kwizinto eziphathekayo ze-matrix ukwenza iibhondi zeekhemikhali. Ngokomzekelo, unyango lwe-oxidation lunokwazisa amaqela e-hydroxyl, amaqela e-carboxyl kunye namanye amaqela asebenzayo kumphezulu we-carbon fibers, ezinokusabela kunyeepoxyamaqela kwi-resin matrix kunye nokunye ukwenza iibhondi ezidibeneyo. Amandla ale ntambo yeekhemikhali iphezulu kakhulu kunokokubambisa umzimba, okuphucula kakhulu amandla okudibanisa phakathi kwe-carbon fiber kunye ne-matrix material.

Amandla angaphezulu kwe-carbon fiber esebenzayo nawo ayanda kakhulu. Ukunyuka kwamandla angaphezulu kwenza kube lula ukuba i-carbon fiber ifakwe kwizinto eziphathekayo ze-matrix, ngaloo ndlela iququzelele ukusasazeka kunye nokungena kwezinto ze-matrix ebusweni be-carbon fiber. Kwinkqubo yokulungiselela ama-composites, izinto ze-matrix zinokusasazwa ngokulinganayo malunga ne-carbon fibers ukwenza isakhiwo esixineneyo. Oku akugcini nje ukuphucula iimpawu zemishini yezinto ezidibeneyo, kodwa ziphucula ezinye iimpawu zayo, ezifana nokuchasana nokubola kunye nokuzinza kwe-thermal.

Iifayibha zekhabhoni ezisebenzayo zineengenelo ezininzi zokulungiselela imidibaniso ye-carbon fiber.

Ngokubhekiselele kwiipropathi zoomatshini, amandla okudibanisa phakathi kwezinto ezisebenzayoiifayibha zekhabhonikwaye izinto ze-matrix ziphuculwe kakhulu, okwenza ukuba ii-composites zibe ngcono ukudlulisa uxinzelelo xa ziphantsi kwamandla angaphandle. Oku kuthetha ukuba iipropathi zoomatshini zee-composites ezifana namandla kunye nemodyuli ziphuculwe kakhulu. Ngokomzekelo, kwintsimi ye-aerospace, efuna iimpawu eziphezulu kakhulu zemishini, iindawo zenqwelomoya ezenziwe nge-activated carbon fiber composites ziyakwazi ukumelana nemithwalo emikhulu yokubhabha kunye nokuphucula ukhuseleko kunye nokuthembeka kwenqwelomoya. Kwintsimi yeempahla zemidlalo, ezifana nezakhelo zebhayisikili, iiklabhu zegalufa, njl., i-carbon fiber composites esebenzayo inokunika amandla angcono kunye nokuqina, ngelixa ukunciphisa ubunzima kunye nokuphucula amava abadlali.

Ngokubhekiselele kwi-corrosion resistance, ngenxa yokungeniswa kwamaqela asebenzayo asebenzayo kumphezulu we-carbon fibers esebenzayo, la maqela asebenzayo angenza ukudibanisa kweekhemikhali ezizinzile kunye nezinto ze-matrix, ngaloo ndlela kuphuculwe ukuxhathisa kwe-corrosion ye-composites. Kwezinye iimeko ezirhabaxa zokusingqongileyo, ezinje ngemekobume yaselwandle, ishishini lemichiza, njalo njalo, ivuliwei-carbon fiber compositesinokumelana ngcono nokukhukuliseka kwemithombo yeendaba eyonakalisayo kwaye yandise ubomi benkonzo. Oku kubaluleke kakhulu kwezinye izixhobo kunye nezakhiwo ezisetyenziswa kwindawo enzima ixesha elide.

Ngokumalunga nokuzinza kwe-thermal, i-interfacial bonding efanelekileyo phakathi kwe-carbon fiber esebenzayo kunye ne-matrix material inokuphucula ukuzinza kwe-thermal ye-composites. Ngaphantsi kwendawo yokushisa ephezulu, ama-composites anokugcina iipropati ezingcono zoomatshini kunye nokuzinza kwe-dimensional, kwaye zincinci kakhulu kwi-deformation kunye nomonakalo. Oku kwenza ukuba imidibaniso ye-carbon fiber isebenze ibe nethemba losetyenziso olubanzi kwizicelo zobushushu obuphezulu, njengendawo yenjini yemoto kunye neendawo ezitshisayo ze-injini yomoya.

Ngokubhekiselele ekusebenzeni kokusebenza, iifayili zekhabhoni ezisebenzayo ziye zandisa umsebenzi ongaphezulu kunye nokuhambelana okungcono kunye nempahla ye-matrix. Oku kwenza kube lula ukuba izinto ze-matrix zingene kwaye zinyange kumphezulu we-carbon fiber ngexesha lokulungiswa kwezinto ezidibeneyo, ngaloo ndlela kuphuculwe ukusebenza kakuhle kunye nomgangatho wemveliso. Kwangaxeshanye, ukuyilwa kweecomposites ze-carbon fiber composite nazo ziphuculwe, zivumela ukuba zenziwe ngokwezifiso kwizicelo ezahlukeneyo kunye nokuhlangabezana neemfuno ezahlukeneyo zobunjineli.

Ngoko ke, kusebenze unyango lweiifayibha zekhabhonilikhonkco eliphambili ekulungiseleleni i-high-performance carbon fiber composites. Ngokusebenzisa unyango olusebenzayo, ubume bomphezulu bekhabhon fiber bunokuphuculwa ukwandisa uburhabaxa bomphezulu, ukwazisa amaqela asebenzayo asebenzayo, kunye nokuphucula amandla angaphezulu, ukuze kuphuculwe amandla okudibanisa ubuso phakathi kwekhabhon fiber kunye nemathiriyeli ye-matrix, kwaye ubeke isiseko sokulungiselela imidibaniso yekhabhoni yefiber eneempawu ezibalaseleyo zoomatshini, ukuxhathisa ukubola, ukuzinza kwe-thermal kunye nokusebenza kokusebenza. Ngenkqubela phambili eqhubekayo yesayensi kunye nobuchwepheshe, kukholelwa ukuba iteknoloji ye-carbon fiber activation iya kuqhubeka nokuvuselela kunye nokuphuhlisa, ukubonelela ngenkxaso enamandla yokusetyenziswa okubanzi kwee-carbon fiber composites.

I-Shanghai Orisen yeTekhnoloji eNtsha yeTekhnoloji Co., Ltd

M: +86 18683776368(kwaye whatsapp)

T: +86 08383990499

Email: grahamjin@jhcomposites.com

Idilesi: NO.398 New Green Road Xinbang Town Songjiang District, Shanghai

Ixesha lokuposa: Sep-04-2024