IiResins zePolyester zoMgangatho oPhezulu wokuVeliswa kweFayibha yeGlasi

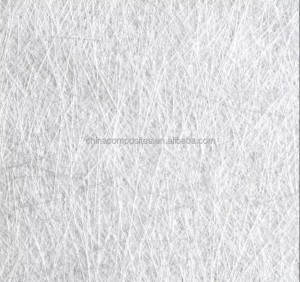

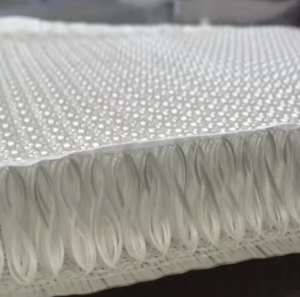

I-KINGDODA yenza i-polyester resins ezikumgangatho ophezulu:

NjengoMvelisi odumileyo weeMveliso zoShishino, siyazingca ngokuvelisa iPolyester Resins ezikumgangatho ophezulu ngamaxabiso akhuphisanayo. Iimveliso zethu zenziwa phantsi kweenkqubo ezingqongqo zolawulo lomgangatho, ziqinisekisa ukuba iireyini eziveliswayo zihlala zihlangabezana nemigangatho ephezulu yoshishino.

Iireyini zethu zepolyester zokuvelisa i-fiberglass zizisombululo eziphezulu zokusebenza ezibonelela ngamandla akhethekileyo, ukunamathela kunye nokuchasana namanzi, ubushushu kunye neekhemikhali. Sinikezela ngezisombululo zemveliso enokwenziwa ngokwezifiso ukuze sihlangabezane neemfuno ezahlukeneyo zesicelo, sisenza iqabane elifanelekileyo kwiimfuno zakho zokuvelisa i-fiberglass. Amaxabiso ethu akhuphisanayo neenkonzo zonikezelo zisenza sahluke kushishino. Qhagamshelana ne-KINGDODA namhlanje ukuze ufunde ngakumbi malunga neemveliso zethu kunye nendlela esinokukunceda ngayo ukuphumeza iinjongo zakho zokuvelisa i-fiberglass.