Ho thoe'ng haeba likhalase tsa khalase tse matlafatsang polymer (GFRP) li ka kopanngoa qetellong ea bophelo ba tsona ba bohlokoa, ho phaella ho mashome a lilemo a melemo e tiisitsoeng ea ho fokotsa boima ba 'mele, matla le ho satalla, ho hanyetsa kutu le ho tšoarella? Seo, ka bokhutšoanyane, ke boipiletso ba theknoloji ea ABM Composite.

Khalase ea bioactive, likhoele tse matla haholo

E Thehiloe ka 2014, Arctic Biomaterials Oy (Tampere, Finland) e hlahisitse fiber ea khalase e ka senyehang e entsoeng ka seo ho thoeng ke khalase ea bioactive, eo Ari Rosling, mookameli oa R & D ho ABM Composite, a e hlalosang e le "tlhahiso e khethehileng e entsoeng lilemong tsa bo-1960 e lumellang khalase hore e senyehe tlas'a maemo a 'mele, ha khalase e kenngoa ka har'a 'mele oa eona. sodium, magnesium, phosphates, joalo-joalo, kahoo e baka boemo bo etsang hore masapo a hōle.”

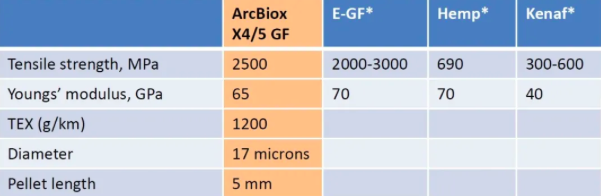

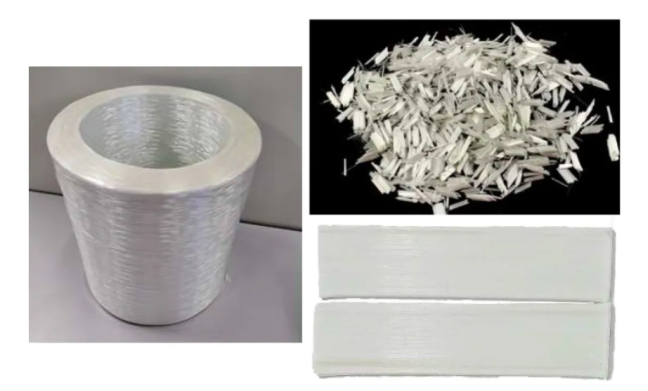

"E na le thepa e tšoanang lefiber ea khalase e se nang alkali (E-glass).” Rosling o itse, "Empa khalase ena ea bioactive ho thata ho e etsa le ho e hula ka har'a likhoele, 'me ho fihlela joale e ntse e sebelisoa feela e le phofo kapa putty. Ho ea kamoo re tsebang kateng, ABM Composite e ne e le k'hamphani ea pele ea ho etsa likhoele tsa khalase tse matla haholo ho tloha ho eona ka tekanyo ea indasteri, 'me hona joale re sebelisa likhoele tsena tsa khalase tsa ArcBiox X4/5 ho matlafatsa mefuta e sa tšoaneng ea lipolasetiki, ho kenyelletsa le li-polymers tse senyehang.

Li-implants tsa bongaka

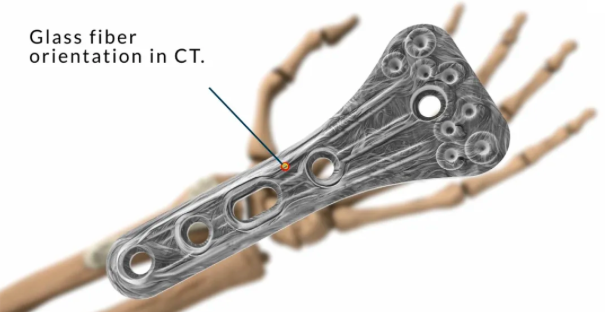

Sebaka sa Tampere, lihora tse peli ka leboea ho Helsinki, Finland, esale e le setsi sa li-polymers tsa biodegradable bakeng sa lits'ebetso tsa bongaka ho tloha ka bo-1980. Rosling oa hlalosa, "E 'ngoe ea li-implants tsa pele tse fumanehang khoebong tse entsoeng ka thepa ena e ile ea hlahisoa Tampere, 'me ke kamoo ABM Composite e qalileng kateng! eo hona joale e leng setsi sa rona sa khoebo ea bongaka".

"Ho na le li-polymer tse ngata tse ka senyehang, tse ka monyehang bakeng sa li-implants." O tsoela pele, "empa lisebelisoa tsa bona tsa mochini li hole le masapo a tlhaho. Re khonne ho ntlafatsa lipolymer tsena tse senyehang e le ho fana ka matla a tšoanang le a lesapo la tlhaho". Rosling o hlokometse hore likhoele tsa khalase tsa ArcBiox tsa boemo ba bongaka ka tlatsetso ea ABM li ka ntlafatsa thepa ea mochini oa li-polymers tsa biodegradable PLLA ka 200% ho isa ho 500%.

Ka lebaka leo, li-implants tsa ABM Composite li fana ka ts'ebetso e phahameng ho feta li-implants tse entsoeng ka li-polymers tse sa matlafatsoang, ha li ntse li le bioabsorbable le ho khothalletsa ho thehoa le ho hōla ha masapo. ABM Composite e boetse e sebelisa mekhoa ea ho beha li-fibre / strand ho etsa bonnete ba hore ho na le mekhoa e metle ea fiber, ho kenyelletsa le ho beha likhoele ka bolelele bohle ba ho kenngoa, hammoho le ho beha likhoele tse eketsehileng libakeng tse ka bang fokola.

Likopo tsa malapa le tsa tekheniki

Ka yuniti ea eona e ntseng e hola ea khoebo ea bongaka, ABM Composite e hlokomela hore li-polymers tse thehiloeng ho bio-le-biodegradable le tsona li ka sebelisoa bakeng sa lisebelisoa tsa kichine, li-cutlery le lintho tse ling tsa ntlo. "Li-polymer tsena tse senyehang ka tlhaho li na le thepa e sa sebetseng hantle ha li bapisoa le lipolasetiki tse entsoeng ka peterole." Rosling o itse, "Empa re ka matlafatsa lisebelisoa tsena ka likhoele tsa rona tsa khalase tse senyehang habonolo, ra li etsa sebaka se setle ho fapana le lipolasetiki tsa khoebo tse thehiloeng ka mesaletsa ea lintho tsa khale bakeng sa lits'ebetso tse fapaneng tsa tekheniki".

Ka lebaka leo, ABM Composite e ekelitse yuniti ea eona ea khoebo ea tekheniki, eo hona joale e hirang batho ba 60. "Re fana ka tharollo e tsitsitseng ea ho qetela ea bophelo (EOL)." Rosling o re, "Molemo oa rona oa bohlokoa ke ho kenya metsoako ena e ka senyehang habonolo tšebetsong ea manyolo a indasteri moo e fetohang mobu." Traditional E-glass ha e sebetse 'me e ke ke ea nyenyefatsa litsing tsena tsa manyolo.

ArcBiox Fiber Composites

ABM Composite e hlahisitse mefuta e fapaneng ea likhoele tsa khalase tsa ArcBiox X4/5 bakeng sa lisebelisoa tse kopaneng, ho tlohalikhoele tse khaotsoengle metsoako ea ho etsa ente holikhoele tse tsoelang pelebakeng sa lits'ebetso tse kang ho bopa masela le pultrusion. Mofuta oa ArcBiox BSGF o kopanya likhoele tsa khalase tse senyehang ka tlhaho le li-resin tsa polyester tse thehiloeng ho bio, 'me li fumaneha ka limaraka tse akaretsang tsa theknoloji le limaraka tsa ArcBiox 5 tse lumelletsoeng ho sebelisoa lits'ebetsong tsa ho ikopanya le lijo.

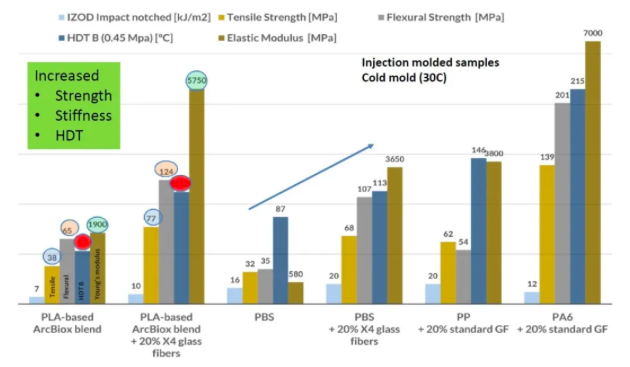

ABM Composite e boetse e batlisitse mefuta e fapaneng ea li-polymers tse nang le biodegradable le bio-based ho kenyelletsa Polylactic Acid (PLA), PLA le Polybutylene Succinate (PBS). Setšoantšo se ka tlase se bontša kamoo likhoele tsa khalase tsa X4/5 li ka ntlafatsang ts'ebetso ho qothisana lehlokoa le li-polymers tse matlafalitsoeng tsa khalase tse kang polypropylene (PP) esita le polyamide 6 (PA6).

ABM Composite e boetse e batlisitse mefuta e fapaneng ea li-polymers tse nang le biodegradable le bio-based, ho kenyelletsa Polylactic Acid (PLA), PLA le Polybutylene Succinate (PBS). Setšoantšo se ka tlase se bontša kamoo likhoele tsa khalase tsa X4/5 li ka ntlafatsang ts'ebetso ho qothisana lehlokoa le li-polymers tse matlafalitsoeng tsa khalase tse kang polypropylene (PP) esita le polyamide 6 (PA6).

Tšireletseho le Motsoako

Haeba metsoako ee e khona ho bola, e tla tšoarella nako e kae? "Lithapo tsa rona tsa khalase tsa X4/5 ha li qhibilihe ka metsotso e mehlano kapa bosiu bo le bong joalo ka ha tsoekere e etsa, 'me le ha thepa ea bona e tla senyeha ha nako e ntse e ea, e ke ke ea bonahala." Rosling o re, "Ho theola boemo ka katleho, re hloka mocheso o phahameng le mongobo ka nako e telele, joalo ka ha li fumanoa ka har'a vivo kapa ka har'a liqubu tsa manyolo a indasteri. e sa bolokehang ho sebelisoa”.

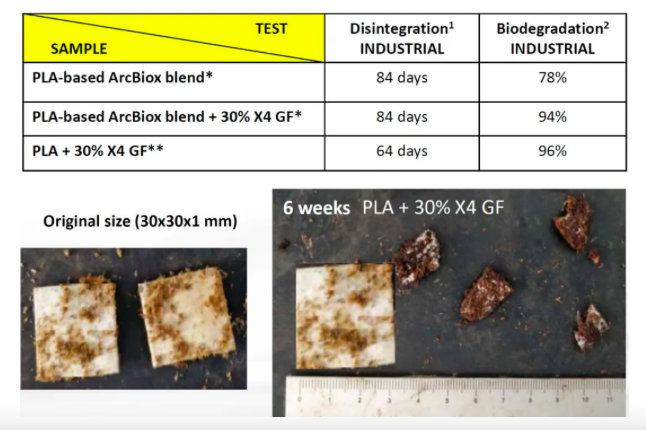

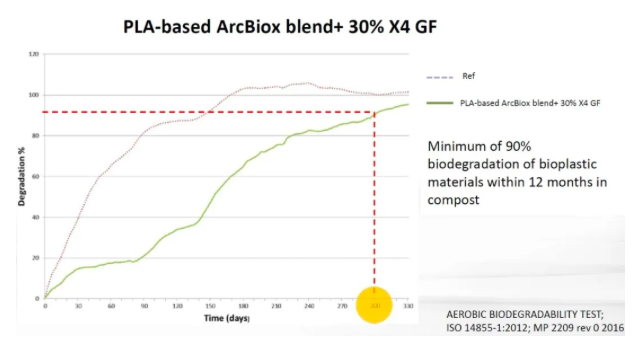

Leha ho le joalo, ho bohlokoa hore ha metsoako ena e lahloa qetellong ea bophelo ba eona ba bohlokoa, e fihlelle litlhoko tse tloaelehileng tse hlokahalang bakeng sa manyolo, 'me ABM Composite e entse letoto la liteko ho paka hore e fihlela litekanyetso tsena. "Ho ea ka litekanyetso tsa ISO (bakeng sa manyolo a indasteri), biodegradation e lokela ho etsahala nakong ea likhoeli tse 6 le ho bola nakong ea likhoeli tse 3 / matsatsi a 90". Rosling o re, "Ho bola ho bolela ho beha sampuli ea teko / sehlahisoa ka har'a biomass kapa manyolo ka mor'a matsatsi a 90, setsebi se hlahloba biomass se sebelisa sefe. Ka mor'a libeke tse 12, bonyane karolo ea 90 lekholong ea sehlahisoa e lokela ho feta ka har'a sefe ea 2 mm × 2 mm".

Biodegradation e khethoa ka ho sila lisebelisoa tsa moroetsana hore e be phofo le ho lekanya kakaretso ea CO2 e lokolloa ka mor'a matsatsi a 90. Sena se lekola hore na ke bokae ba khabone ea tšebetso ea manyolo e fetoloang metsi, biomass le CO2. "Ho fetisa tlhahlobo ea manyolo ka liindasteri, karolo ea 90 lekholong ea theoretical 100 per cent CO2 ho tloha ts'ebetsong ea manyolo e tlameha ho finyelloa (ho ipapisitse le carbon content)".

Rosling o re ABM Composite e fihletse litlhoko tsa ho bola le ho senyeha ha lintho tse phelang, 'me liteko li bontšitse hore ho eketsoa ha fiber ea eona ea khalase ea X4 e hlile e ntlafatsa biodegradability (sheba tafole e ka holimo), e leng 78% feela bakeng sa motsoako o sa tiisetsoang oa PLA, mohlala. Oa hlalosa, "Leha ho le joalo, ha likhalase tsa rona tsa 30% tsa likhalase tse senyehang li kenngoa, biodegradation e ile ea eketseha ho 94%, ha litekanyetso tsa ho senyeha li ntse li le ntle".

Ka lebaka leo, ABM Composite e bonts'itse hore thepa ea eona e ka netefatsoa e le manyolo ho latela EN 13432. Liteko tseo thepa ea eona e seng e fetile ho fihlela joale li kenyelletsa ISO 14855-1 bakeng sa biodegradability ea ho qetela ea aerobic ea lisebelisoa tse tlas'a maemo a laoloang a manyolo, ISO 16929 bakeng sa ho bola ho laoloang ke aerobic, litlhoko tsa ISO DIN 34 CD0 EN8 bakeng sa CD2 EN. tlhahlobo ea phytotoxicity, ISO DIN EN 13432.

CO2 e lokolloa nakong ea manyolo

Nakong ea composting, CO2 e hlile e lokolloa, empa e meng e sala mobung ebe e sebelisoa ke limela. Composting e 'nile ea ithutoa ka lilemo tse mashome, ka bobeli e le ts'ebetso ea indasteri hape e le ts'ebetso ea morao-rao ea manyolo e lokollang CO2 e fokolang ho feta mekhoa e meng ea ho lahla litšila,' me composting e ntse e nkoa e le mokhoa oa ho boloka tikoloho le oa ho fokotsa carbon footprint.

Ecotoxicity e kenyelletsa tlhahlobo ea biomass e hlahisoang nakong ea manyolo le limela tse holisitsoeng ka biomass ena. "Sena ke ho etsa bonnete ba hore manyolo a lihlahisoa tsena ha a lematse limela tse ntseng li hola." Ho boletse Rosling. Ho phaella moo, ABM Composite e bontšitse hore thepa ea eona e finyella litlhoko tsa ho senyeha ha limela tlas'a maemo a manyolo a malapeng, ao hape a hlokang 90% ea ho senyeha ha limela, empa ka nako ea likhoeli tse 12, ha ho bapisoa le nako e khutšoanyane ea manyolo a indasteri.

Lisebelisoa tsa indasteri, tlhahiso, litšenyehelo le kholo ea nako e tlang

Lisebelisoa tsa ABM Composite li sebelisoa lits'ebetsong tse ngata tsa khoebo, empa tse ling li ke ke tsa senoloa ka lebaka la litumellano tsa lekunutu. Rosling o re: "Re odara lisebelisoa tsa rona hore li lumellane le lits'ebetso tse joalo ka linoelo, li-sauers, lipoleiti, lijana le lijana tsa polokelo ea lijo, empa li boetse li sebelisoa e le mokhoa o mong oa lipolasetiki tse entsoeng ka peterole ka lijaneng tsa litlolo le lintho tse kholo tsa ntlo. Haufinyane tjena, lisebelisoa tsa rona li khethiloe ho sebelisoa ha ho etsoa likarolo tsa metjhini e meholo ea indasteri e hlokang ho nkeloa sebaka ke likhalase tsa X2 libekeng tse ling le tse ling tse peli. matlafatso, likarolo tsena tsa mechine li ka etsoa ka mokhoa o hlokahalang oa ho roala 'me li boetse li na le manyolo ka mor'a ho sebelisoa Ena ke tharollo e khahlehang bakeng sa bokamoso bo haufi ha lik'hamphani tsena li tobane le phephetso ea ho kopana le melao e mecha ea tikoloho le CO2 ".

Rosling o ile a phaella ka ho re, "Ho boetse ho na le thahasello e ntseng e eketseha ea ho sebelisa likhoele tsa rona tse tsoelang pele mefuteng e fapaneng ea masela le li-nonwovens ho etsa likarolo tsa mohaho bakeng sa indasteri ea kaho. Re boetse re bona thahasello ea ho sebelisa likhoele tsa rona tse nang le biodegradable tse nang le PA kapa PP ea bio-based empa e sa senyeha le lisebelisoa tsa thermoset".

Hona joale, X4/5 fiberglass e theko e boima ho feta E-glass, empa palo ea tlhahiso le eona e batla e le nyenyane, 'me ABM Composite e ntse e phehella menyetla e mengata ea ho atolosa lits'ebetso le ho nolofatsa mokhoa o fihlang ho lithane tse 20,000 ka selemo ha tlhokahalo e ntse e hōla, e ka thusang ho fokotsa litšenyehelo. Leha ho le joalo, Rosling o re maemong a mangata litšenyehelo tse amanang le ho tšoarella le litlhoko tse ncha tsa taolo ha li e-s'o nahanoe ka botlalo. Ho sa le joalo, ho potlaka ha ho pholosa polanete ho ntse ho eketseha. "Mokhatlo o se o ntse o batla lihlahisoa tse ling tse thehiloeng ho bioloji." Oa hlalosa, "Ho na le lintho tse ngata tse susumetsang ho sutumelletsa theknoloji ea ho tsosolosa pele, lefats'e le hloka ho tsamaea ka potlako ho sena 'me ke nahana hore sechaba se tla eketsa ts'ebetso ea sona bakeng sa lihlahisoa tse thehiloeng linthong tse phelang nakong e tlang".

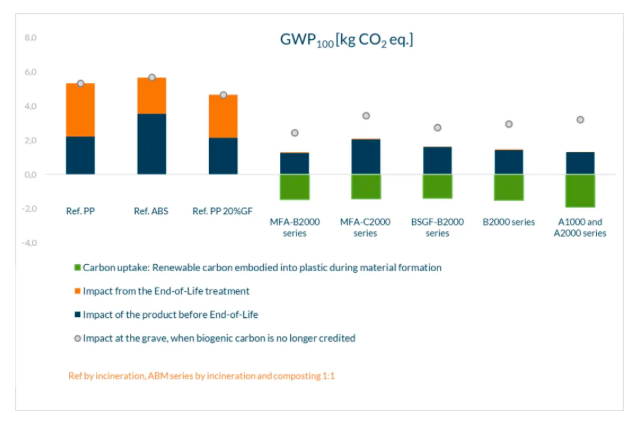

LCA le Molemo oa Moshoelella

Rosling o re thepa ea ABM Composite e fokotsa tlhahiso ea khase e futhumatsang lefatše le tšebeliso ea matla a sa tsosolositsoeng ka liphesente tse 50-60 ka kilogram. "Re sebelisa Environmental Footprint Database 2.0, dataset e ngolisitsoeng ka molao ea GaBi, le lipalo tsa LCA (Life Cycle Analysis) bakeng sa lihlahisoa tsa rona ho latela mokhoa o boletsoeng ho ISO 14040 le ISO 14044 ″.

"Hajoale, ha likhomphutha li fihla pheletsong ea nako ea bophelo ba tsona, ho hlokahala matla a mangata ho chesa kapa ho senya litšila tse kopaneng le lihlahisoa tsa EOL, 'me ho pshatla le ho etsa manyolo ke khetho e ntle,' me ke e 'ngoe ea litlhahiso tsa bohlokoa tseo re fanang ka tsona, 'me re fana ka mofuta o mocha oa ho sebelisoa hape." Rosling o re, "Fiberglass ea rona e entsoe ka likarolo tsa tlhaho tsa liminerale tse seng li ntse li le teng mobung. Joale ke hobane'ng ha manyolo ka litlama a EOL a sa qhibilihe, kapa a qhala likhoele tse tsoang mefuteng e sa senyeheng ka mor'a ho chesoa ebe o li sebelisa e le manyolo? Ena ke khetho ea ho tsosolosa ea thahasello ea sebele ea lefats'e ".

Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368(hape WhatsApp)

T: +86 08383990499

Email: grahamjin@jhcomposites.com

Aterese: NO.398 New Green Road Xinbang Town Songjiang District, Shanghai

Nako ea poso: May-27-2024