In today’s era of rapid technological advancement, carbon fiber composites are making a name for themselves in a wide range of fields due to their superior performance. From high-end applications in aerospace to the daily needs of sporting goods, carbon fiber composites have shown great potential. However, to prepare high-performance carbon fiber composites, activation treatment of carbon fibers is a crucial step.

Carbon fiber surface electron microscope picture

Carbon fiber, a high-performance fiber material, has many compelling properties. It is mainly composed of carbon and has an elongated filamentary structure. From the point of view of the surface structure, the surface of carbon fiber is relatively smooth and has fewer active functional groups. This is due to the fact that during the preparation of carbon fibers, high-temperature carbonization and other treatments make the surface of carbon fibers present a more inert state. This surface property brings a series of challenges to the preparation of carbon fiber composites.

The smooth surface makes the bond between carbon fiber and matrix material weak. In the preparation of composites, it is difficult for the matrix material to form a strong bond on the surface of the carbon fiber, which affects the overall performance of the composite material. Secondly, the lack of active functional groups limits the chemical reaction between carbon fibers and matrix materials. This makes the interfacial bonding between the two mainly rely on physical effects, such as mechanical embedding, etc., which is often not stable enough and is prone to separation when subjected to external forces.

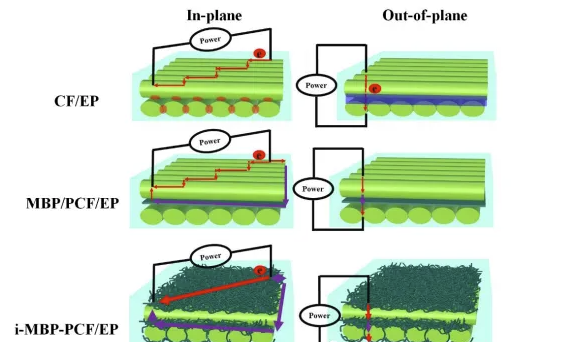

Schematic diagram of interlayer reinforcement of carbon fiber cloth by carbon nanotubes

In order to solve these problems, activation treatment of carbon fibers becomes necessary. Activated carbon fibers show significant changes in several aspects.

Activation treatment increases the surface roughness of carbon fibers. Through chemical oxidation, plasma treatment and other methods, tiny pits and grooves can be etched into the surface of carbon fibers, making the surface rough. This rough surface increases the contact area between the carbon fiber and the substrate material, which improves the mechanical bond between the two. When the matrix material is bonded to the carbon fiber, it is better able to embed itself into these rough structures, forming a stronger bond.

The activation treatment can introduce an abundance of reactive functional groups on the surface of the carbon fiber. These functional groups can react chemically with the corresponding functional groups in the matrix material to form chemical bonds. For example, oxidation treatment can introduce hydroxyl groups, carboxyl groups and other functional groups on the surface of carbon fibers, which can react with the epoxy groups in the resin matrix and so on to form covalent bonds. The strength of this chemical bonding is much higher than that of physical bonding, which greatly improves the interfacial bonding strength between the carbon fiber and the matrix material.

The surface energy of the activated carbon fiber also increases significantly. The increase in surface energy makes it easier for the carbon fiber to be wetted by the matrix material, thus facilitating the spreading and penetration of the matrix material on the surface of the carbon fiber. In the process of preparing composites, the matrix material can be more evenly distributed around the carbon fibers to form a more dense structure. This not only improves the mechanical properties of the composite material, but also improves its other properties, such as corrosion resistance and thermal stability.

Activated carbon fibers have multiple advantages for the preparation of carbon fiber composites.

In terms of mechanical properties, the interfacial bonding strength between the activated carbon fibers and the matrix material is greatly improved, which enables the composites to better transfer stresses when subjected to external forces. This means that the mechanical properties of composites such as strength and modulus are significantly improved. For example, in the aerospace field, which requires extremely high mechanical properties, aircraft parts made with activated carbon fiber composites are able to withstand greater flight loads and improve the safety and reliability of the aircraft. In the field of sporting goods, such as bicycle frames, golf clubs, etc., activated carbon fiber composites can provide better strength and stiffness, while reducing weight and improving the athletes’ experience.

In terms of corrosion resistance, due to the introduction of reactive functional groups on the surface of activated carbon fibers, these functional groups can form more stable chemical bonding with the matrix material, thus improving the corrosion resistance of the composites. In some harsh environmental conditions, such as the marine environment, chemical industry, etc., the activated carbon fiber composites can better resist the erosion of corrosive media and extend the service life. This is of great significance for some equipment and structures that are used in harsh environments for a long time.

In terms of thermal stability, good interfacial bonding between activated carbon fiber and matrix material can improve the thermal stability of composites. Under the high temperature environment, the composites can maintain better mechanical properties and dimensional stability, and are less prone to deformation and damage. This makes the activated carbon fiber composites have broad application prospects in high-temperature applications, such as automotive engine parts and aviation engine hot end parts.

In terms of processing performance, the activated carbon fibers have increased surface activity and better compatibility with the matrix material. This makes it easier for the matrix material to infiltrate and cure on the surface of the carbon fiber during the preparation of the composite material, thus improving the processing efficiency and product quality. At the same time, the designability of the activated carbon fiber composites is also enhanced, allowing them to be customized for different applications and to meet a variety of complex engineering requirements.

Therefore, activation treatment of carbon fibers is a key link in the preparation of high-performance carbon fiber composites. Through the activation treatment, the surface structure of carbon fiber can be improved to increase the surface roughness, introduce active functional groups, and improve the surface energy, so as to improve the interfacial bonding strength between carbon fiber and matrix material, and lay the foundation for the preparation of carbon fiber composites with excellent mechanical properties, corrosion resistance, thermal stability and processing performance. With the continuous progress of science and technology, it is believed that carbon fiber activation technology will continue to innovate and develop, providing stronger support for the wide application of carbon fiber composites.

Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368(also whatsapp)

T:+86 08383990499

Email: grahamjin@jhcomposites.com

Address: NO.398 New Green Road Xinbang Town Songjiang District,Shanghai

Post time: Sep-04-2024