Recently with the rapid development of highway engineering construction, the technology of asphalt concrete structures has made rapid progress and has reached a large number of mature and excellent technical achievements.

At present, asphalt concrete has been widely used in the field of highway construction, highlighting its important position in construction projects. However, while seeing the achievements made, we should also be aware that the deformation and damage problems of asphalt concrete pavement are becoming increasingly serious.

Severe potholes and deformations on the road surface can have a significant impact on driving safety. Basalt fiber chopped strand is a new type of fiber material, with its unique mechanical properties, good stability, and high cost performance ratio, making it an excellent concrete reinforcement material.

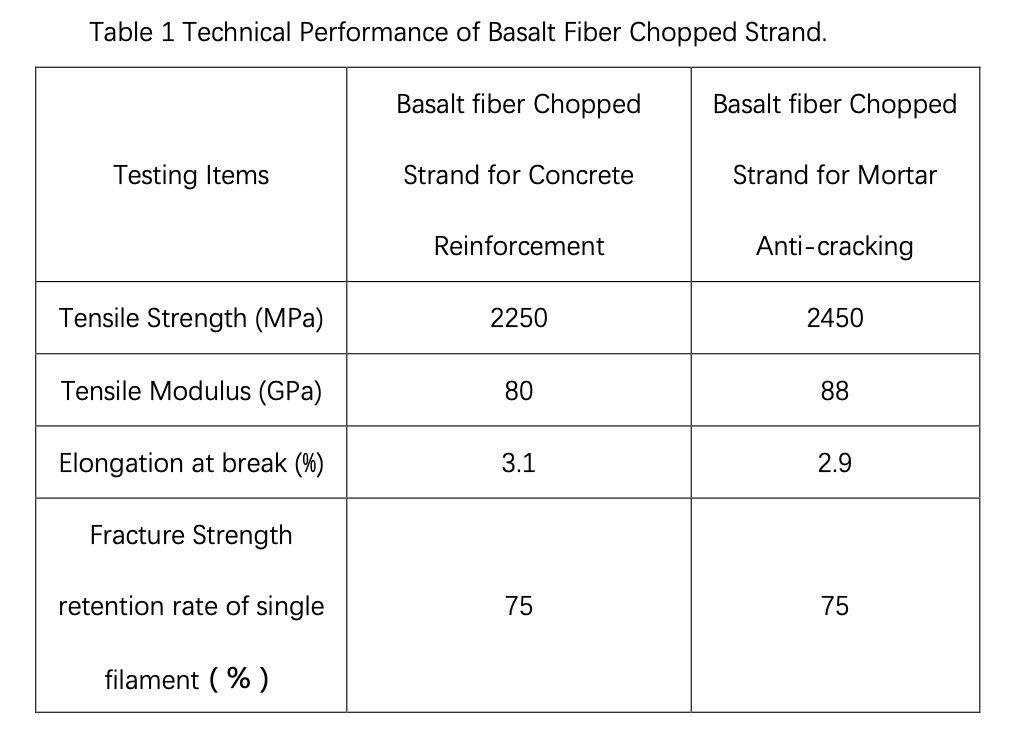

Performance of basalt fiber chopped strand

Basalt fiber chopped strand is an inorganic mineral fiber with a length of less than 50mm, which is cut from the corresponding basalt fiber substrate and can be uniformly dispersed in concrete.

Basalt fiber chopped strand have excellent properties such as high axial tensile strength and high modulus, with a tensile strength of 2250-2550MPa and an elastic modulus greater than 78 GPa; Short cut basalt has outstanding high temperature resistance, allowing it to work continuously in the range of -269 to 650 degrees Celsius; It has high corrosion resistance and chemical stability in corrosive media (acid, alkali, salt solutions), and can maintain higher resistance to alkaline corrosion in saturated alkaline solutions and cement and other alkaline media. The retention rate of single wire fracture strength is greater than 75%; Basalt fiber chopped strand can also be compatible with inorganic adhesives, with a moisture absorption rate of less than 1% and an absorption capacity that does not change over time, which proves their material stability, long lifespan, and environmental compatibility during use; In addition, basalt fiber chopped strand also have good insulation performance, high-temperature filtration, radiation resistance, and good wave permeability. Table 1 shows the technical performance indicators of basalt fiber chopped strand.

Application analysis of basalt fiber chopped strand in asphalt concrete pavement

Basalt fiber chopped strand asphalt concrete is mainly made by adding basalt fiber chopped strand in an appropriate proportion to asphalt concrete materials for road surfaces, and mixing them under strict mixing ratio, temperature, humidity, mixing time, and other conditions.

As is well known, in addition to basalt fibers, fiber materials such as polyester fibers, wood fibers, and mineral wool fibers can all be used as reinforcement materials in the reinforcement of asphalt concrete. However, the use of these fibers for many years shows that there are some problems when they are used as reinforcement materials in asphalt concrete, such as weak anti-aging performance, weak strengthening effect, and harmful to human health.

The emergence of basalt fiber chopped strand has filled a gap in both materials and methods, effectively solving the problems existing in existing asphalt concrete pavement and playing a great role in promoting it. Its role in asphalt concrete pavement is manifested in the following aspects:

(1) Basalt fiber chopped strand, due to their low water absorption, can be added to asphalt concrete to increase the thickness of the asphalt pavement, making it less prone to cracking and instability of the roadbed due to water absorption and expansion.

(2) Basalt fiber chopped strand can not only take advantage of their high modulus and tensile strength, just like steel fibers, to prevent further expansion of cracks after they appear, but also to avoid situations where steel fibers are prone to clumping during mixing, which is not conducive to pumping, and the construction process is complex.

(3) The chopped basalt fiber is a typical nitric acid fiber, which has good compatibility. Because its surface is fluffy, it can absorb asphalt, so that the basalt fiber is evenly distributed in the concrete, forming a solid interface layer, so as to improve the aging resistance and durability of asphalt concrete pavement.

(4) Basalt fiber chopped strand have excellent temperature and strain resistance. Its working temperature range is between minus 270 to 651 degrees Celsius, and it can maintain stability in high temperature environments. It can also prevent the slip of mineral elements in concrete, enhance its stability, and effectively improve the high-temperature resistance to rutting strain of asphalt concrete pavement.

In addition, basalt fiber chopped strand also have excellent low-temperature resistance, especially for improving the low-temperature fission resistance of asphalt concrete pavement.

Adding basalt fiber chopped strand to asphalt concrete can improve the impact resistance, rutting resistance, and mechanical properties of asphalt concrete pavement. Specifically, basalt fiber chopped strand play a crucial role in asphalt concrete pavement, such as crack resistance, anti-seepage, durability, impact resistance, tensile strength, and aesthetics.

Construction methods and precautions for basalt fiber chopped strand asphalt concrete

(1) Construction temperature

The construction temperature of basalt fiber chopped strand asphalt concrete should not be too low, because basalt fiber chopped strand will enhance the viscosity of asphalt. Therefore, the construction temperature of short cut basalt asphalt concrete should be higher than that of ordinary asphalt concrete, otherwise it will be easy to cause uneven mixing.

(2) Construction quality control

The construction quality control of basalt fiber chopped strand asphalt concrete should pay attention to the quality control of the inspection, measurement, and mixing process of each component material in the basalt fiber chopped strand concrete.

In actual construction, different amounts of short cut basalt should be selected within a reasonable range according to the engineering requirements. Due to the fact that basalt fiber chopped strand themselves do not react with other concrete components and admixtures, the fiber content will not change the mix proportion of the original concrete.

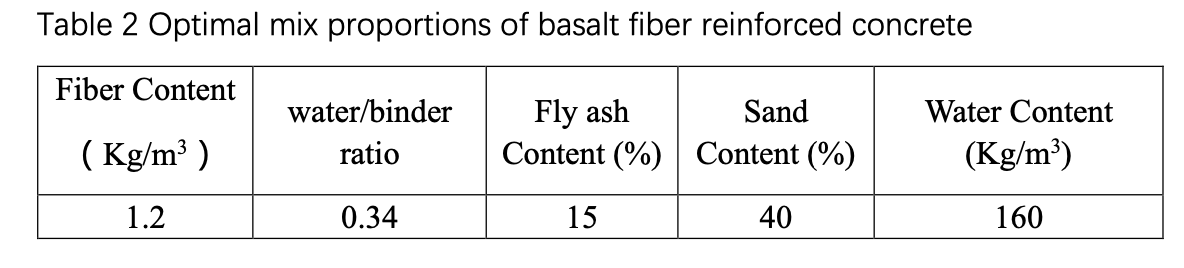

During the construction period, the quality of various materials in basalt fiber chopped strand reinforced concrete should be calculated and determined based on the construction mix proportion and one-time mixing amount. He Junyong, Tian Chengyu, and others studied the optimal mix proportion of basalt fiber reinforced concrete through orthogonal design experimental methods. Five factors, including fiber content, water cement ratio, fly ash content, sand ratio, and unit water consumption, were selected as the main factors in the experiment.

Table 2 shows the optimal mix proportions of basalt fiber reinforced concrete obtained through experiments.

Experiments have shown that the higher the content ratio of basalt fiber chopped strand, the better the crack resistance effect of concrete, at 1.2kg/m ³ Within a certain range, the compressive strength of concrete increases with the increase of the content of basalt fiber chopped strand, then decreases and increases in a curved form.

(3) Feeding sequence and method

In the mixing process of basalt fiber chopped strand asphalt concrete, the feeding sequence of basalt fiber chopped strand should be considered. When using, add basalt fiber chopped strand together with aggregates such as sand and stone. It is best to add sand and stone at the same time. Add basalt fiber chopped strand to the sand, then add asphalt and wet mix and stir.

The fiber addition method can be divided into manual addition and automatic addition. Artificial addition refers to manually adding basalt fiber chopped strand that have been weighed after hot aggregates are added to the mixing tank. However, its disadvantages are high labor intensity, low mixing uniformity, and the need to extend the mixing time according to the actual situation to ensure that the fibers are dispersed more evenly in asphalt concrete.

Automatic feeding refers to the use of a basalt fiber feeder to automatically measure the amount of material to be added and put it into the mixing pot along with the hot aggregate of the mixer. The fiber feeder has advantages such as automatic metering, pre crushing, and air conveying mechanism, and has convenient, fast, and accurate fiber addition functions. In practical applications, appropriate methods should be selected based on the actual construction situation.

(4) Paving precautions

Firstly, attention should be paid to the cleanliness of the paving surface; Then preheat the paver’s ironing plate to 120 degrees Celsius, while paying attention to the paving speed, controlling it at around 3 to 4 meters per minute; The coefficient of loosening should be determined based on the actual trial laying of the project; The paving temperature should be maintained at 160 degrees Celsius.

(5) Forming and curing

Concrete mixed with basalt fiber chopped strand should have no special requirements during molding, except for ensuring full compaction of asphalt concrete. It should be compacted as much as possible under high temperature conditions.

Application examples of basalt fiber chopped strand in asphalt concrete pavement

The Haining Interchange Connection Line of Jiashao Expressway (with a pavement structure of 20cm cement stabilized crushed stone base and+6cm (AC-20C) asphalt concrete and+4cm (AC-16C) asphalt concrete) and the 08 Provincial Road have been approved by the Haining Municipal Science and Technology Bureau. In order to explore scientific and effective methods to improve the road’s resistance to rutting, ensure the safety and smoothness of the highway, and strive to treat rutting diseases in a simple and convenient manner, with a short construction period and low maintenance costs, Curing tests were conducted using modified asphalt concrete with basalt fiber chopped strand.

From the perspective of treatment effect, the addition of basalt fiber chopped strand greatly improves the high-temperature stability of asphalt concrete pavement, enhances the durability of the pavement, prolongs its service life, and reduces the occurrence of secondary ruts, providing a strong guarantee for driving safety.

Conclusion

Basalt fiber chopped strand, with their unique mechanical properties, good stability, and low cost, make them an excellent concrete reinforcement material. The application prospects of basalt fiber chopped strand reinforced asphalt concrete are very broad. Both economic and social benefits will achieve a win-win situation, and it will become one of the main building materials in the field of highway construction in the future.

Post time: Mar-13-2024