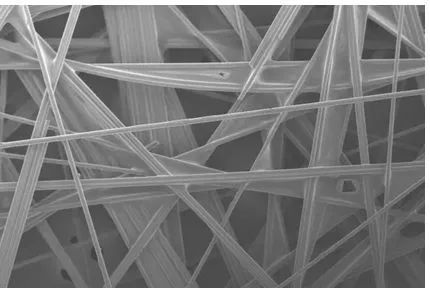

How does a hard stone turn into a fiber as thin as hair?

It's so romantic and magical,

How did it happen?

Origin Of Glass Fiber

Glass Fiber Was First Invented In The USA

In the late 1920s, during the great depression in the United States, the government issued a wonderful Law: the prohibition of alcohol for 14 years, and wine bottle manufacturers were in trouble one after another. Owens Illinois was the largest manufacturer of glass bottles in the United States at that time and could only watch glass furnaces turn off. At this time, a noble man, games slayer, happened to pass by a glass furnace and found that some spilled liquid glass was blown into fiber shape. Games seems like Newton was hit in the head by an apple, and glass fiber has been on the stage of history since then.

A year later, the Second World War broke out and there was a shortage of conventional materials. In order to meet the needs of military combat readiness, glass fiber became a substitute.

People gradually find that this kind of insulation material has many advantages of light quality and high strength. As a result, tanks, aircraft, weapons, bulletproof vests and so on all use glass fiber.

How to define ?

In 2021, the production capacity of glass balls for wire drawing of various crucibles in China was 992000 tons, with a year-on-year increase of 3.2%, which was significantly slower than that of last year. Under the background of "double carbon" development strategy, glass ball kiln enterprises are facing more and more shutdown pressure in terms of energy supply and raw material cost.

The rise of China's glass fiber industry

China's glass fiber industry rose in 1958. After 60 years of development, before the reform and opening up, it mainly served the national defense and military industry, and then turned to civilian use, and achieved rapid development.

Women workers in early winding workshop

By 2008, China's glass fiber tank furnace wire drawing output reached 1.6 million tons, ranking first in the world.

Production Technology Of Glass Fiber

Early crucible wire drawing

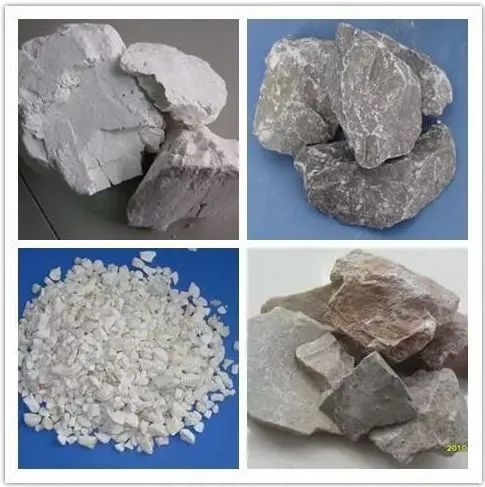

The early production process of glass fiber was mainly the crucible wire drawing method, in which the clay crucible method has been eliminated, and the platinum crucible method needs to be formed twice. Firstly, the glass raw materials are melted into glass balls at high temperature, then the glass balls are melted twice, and the glass fiber filaments are made by high-speed wire drawing.

The disadvantages of this process include high energy consumption, unstable forming process and low labor productivity. At present, this method has been basically eliminated except for a small amount of glass fiber with special components

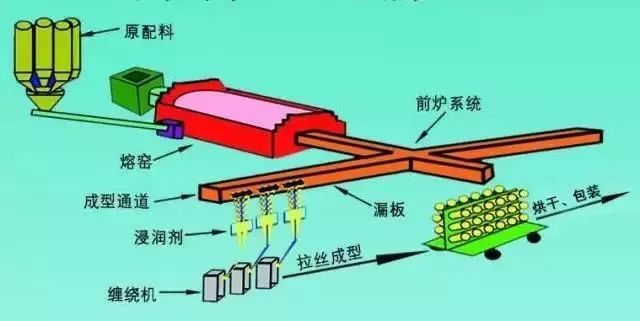

Tank Furnace Wire Drawing

Nowadays, large glass fiber manufacturers adopt this method (after melting various raw materials in the kiln, they directly go through the channel to the special leakage plate to draw the glass fiber precursor).

This one-time molding method has the advantages of low energy consumption, stable process, improved output and quality, which makes the glass fiber industry quickly realize large-scale production. It is known as "a technological revolution of glass fiber industry" in the industry.

Application Of Glass Fiber

It is of strategic significance for the development of glass fiber and new composite materials in the transition and upgrading of traditional stone industry.

It "goes from heaven to earth and can do anything" and contributes to our aerospace industry and transportation industry; It "gets up in the hall and down in the kitchen", has it in the field of energy conservation and environmental protection "tall", and also has it in the field of sports and leisure "grounded"; It "can be thick or thin, flexible switching", which not only meets the hard standard of building materials, but also meets the precision requirements of electronic appliances.

Magic As You - Fiberglass!

Aircraft radome, engine parts, wing components and their interior floors, doors, seats, auxiliary fuel tanks, etc.

Automobile body, automobile seat and high-speed railway body / structure, hull structure, etc.

Wind turbine blade and unit cover, air conditioning exhaust fan, civil grille, etc.

Golf clubs, table tennis rackets, badminton rackets, paddles, skis, etc.

Composite wall, thermal insulation screen window, FRP reinforcement, bathroom, door panel, ceiling, daylighting board, etc

Bridge girder, wharf, expressway pavement, pipeline, etc.

Chemical containers, storage tanks, anti-corrosion grids, anti-corrosion pipelines, etc.

In short, glass fiber is an inorganic non-metallic material with excellent performance. It has the advantages of light weight, high strength, high temperature resistance, chemical corrosion resistance, fatigue resistance and good electrical insulation. It has been widely used in various fields of the national economy, such as construction and infrastructure, automobile and transportation, chemical industry, environmental protection, electronics and electricity, ships and oceans, benefiting the people. (source: Materials Science and Engineering Technology).

Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368(also WhatsApp)

T:+86 08383990499

Email: grahamjin@jhcomposites.com

Address: NO.398 New Green Road Xinbang Town Songjiang District, Shanghai

Post time: Mar-15-2022