Recently, China’s first large-capacity sodium-ion battery energy storage power station – Volin sodium-ion battery energy storage power station put into operation in Nanning, Guangxi. This is the national key research and development program “100 megawatt-hour sodium-ion battery energy storage technology” project demonstration project of the first phase of the project, the installed size of 2.5 megawatts/10 megawatt-hours.

The power station is invested and constructed by Guangxi Power Grid Company of Southern Power Grid, and the scale of this phase is 10 MWh. The total scale of the project will reach 100 MWh, which can generate 73 million degrees of clean electricity annually, The power plant is invested and built by Guangxi Power Grid Company of Southern Power Grid, and the scale of this phase is 10 MWh. The total scale of the project will reach 100 MWh, which can generate 73 million degrees of clean electricity annually, correspondingly reduce carbon dioxide emissions by 50,000 tonnes, and meet the electricity needs of 35,000 residential users.

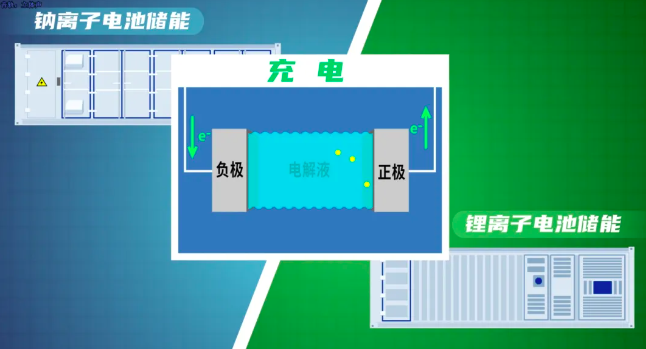

Compared with lithium-ion battery energy storage, “brothers” sodium-ion battery energy storage raw material reserves, easy to extract, low cost, better performance at low temperatures, in large-scale energy storage has obvious advantages. “Sodium-ion battery energy storage in the scale of the development stage, the cost of the cost can be reduced by 20% to 30%, under the premise of fully improve the battery structure and process, improve the utilization rate of materials and cycle life, the cost of electricity can be explored to 0.2 yuan / kWh, is to promote the economic application of new type of storage of an important direction of technology,” the national power energy storage Chen Man, deputy secretary-general of the National Electric Power Storage Technical Committee and strategic-level technical expert of the Southern Power Grid, said.

Although China’s work in the research and development, production, standardisation, market promotion and application of sodium-ion battery products is in full swing, there is no international precedent for the application of sodium-ion battery technology to large-capacity energy storage power stations.

In November 2022, Guangxi Power Grid Company, in conjunction with the South Grid Energy Storage Company, the Institute of Physics of the Chinese Academy of Sciences, Zhongkehai Sodium Technology Co., Ltd. and other units of the project team, officially launched the national key research and development program project sub-topic “100 megawatt-hour sodium-ion battery energy storage system integration technology and application demonstration” research Tackle the task. “We focus on high-performance electric core scale preparation, system integration and safety prevention and control and other key technologies to carry out research, formed with independent intellectual property rights of sodium-ion battery preparation and system integration technology,” the project leader, the South China Grid Guangxi Grid Company, deputy director of the Department of Innovation Gao Lik introduced.

The high-capacity battery cell is the basic unit of the entire sodium-ion battery energy storage system. After one and a half years of research, the project team developed the world’s first long-life, wide temperature zone, high safety 210Ah sodium-ion energy storage battery. “From the performance point of view, our kind of sodium-ion battery has the advantages of wide working temperature zone, fast charging and good multiplicity, and can be charged to 90% in 12 minutes,” said Hu Yongsheng, a researcher at the Institute of Physics, Chinese Academy of Sciences.

As the main technical participants in the project, the SouthGrid Energy Storage Company Energy Storage Research Institute in the lithium battery energy storage system integration and safety prevention and control in the field has a wealth of research experience, undertake the national key research and development program “lithium-ion battery energy storage system life cycle application of safety technology”. “Although the reaction principles of sodium and lithium batteries are similar, the development of a complete energy storage system that combines the charging and discharging characteristics of sodium batteries requires overcoming many new challenges,” said Li Yongqi, a technical expert from SouthGrid Energy Storage Company, with emotion.

Taking the system integration as an example, the project team innovatively adopts a distributed energy storage architecture based on the high voltage of sodium-ion batteries, and the whole system integrates 88 modular converters, realizing a “one-to-one correspondence” with the battery clusters, while the traditional distributed architecture of lithium-ion energy storage system only needs to integrate more than 40 converters. The immediate purpose of doubling the number of converters is to increase capacity availability and energy conversion efficiency. The overall energy conversion efficiency of this sodium battery energy storage system is more than 92%, while lithium batteries are generally less than 90%, which is expected to complement and effectively replace lithium batteries, and be applied to large-scale electrochemical energy storage, electric vehicles, construction machinery and other fields.

As for safety prevention and control, the team has developed a thermal management strategy for the liquid cooling system as well as a complete set of fire prevention and control technologies for the sodium-ion battery energy storage system, such as module-level thermal barrier and high-efficiency fire extinguishing.

The temperature difference between more than 22,000 sodium battery cells in the whole system is controlled within 3 degrees Celsius. The use of both heat dissipation and thermal runaway barrier glass fiber aerogel blanket as a thermal barrier material between the electrical core, the battery monomer thermal runaway spread time from 30 minutes to 2 hours, extended to 4 times, greatly improving the safety of the battery module.

The team developed the liquid nitrogen efficient fire extinguishing, cooling, anti-reignition technology, able to extinguish the initial battery fire within 5 seconds, to do 24 hours without re-ignition and explosion. “The current lithium and sodium energy storage technology to promote the improvement of each other’s characteristics obvious, this set of sodium-ion battery energy storage system research and practical liquid nitrogen efficient fire extinguishing, cooling, anti-reignition technology through lithium-ion battery energy storage system life cycle application of safety technology conversion application in lithium, sodium energy storage system synchronization for the first time in the engineering application,” LiYongQi said.

January 28, 2024, by the Chinese Academy of Engineering Jiang Jianchun academician, Chinese Academy of Sciences, Cheng Shijie academician, Zhang Yue academician, the European Union Academy of Sciences Sun Jinhua academician and other experts of the China Machinery Industry Federation Appraisal Committee on the results of the project to make a review of the appraisal: the overall technology of the “10 MWh sodium ion battery energy storage system for electric energy storage power stations” developed by the project team is at the international leading level.

Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368(also WhatsApp)

T:+86 08383990499

Email: grahamjin@jhcomposites.com

Address: NO.398 New Green Road Xinbang Town Songjiang District, Shanghai

Post time: May-23-2024