As a key member of the advanced composites field, ultra-short carbon fiber, with its unique properties, has triggered widespread attention in many industrial and technological fields. It provides a brand new solution for high performance of materials, and an in-depth understanding of its application technologies and processes is essential to drive the development of related industries.

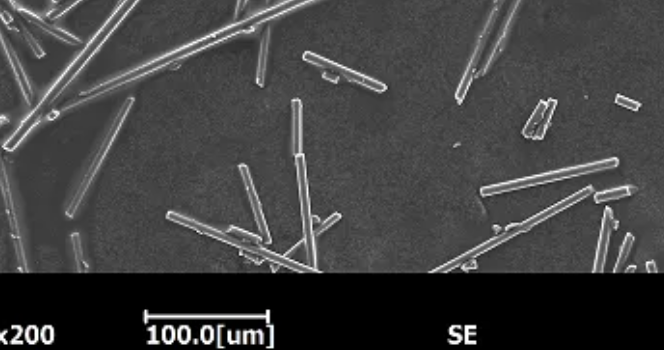

Electron micrographs of ultrashort carbon fibers

Typically, the length of ultra-short carbon fibers is between 0.1 – 5mm, and their density is low at 1.7 – 2g/cm³. With a low density of 1.7 – 2.2g/cm³, a tensile strength of 3000 – 7000MPa and a modulus of elasticity of 200 – 700GPa, these excellent mechanical properties form the basis for its use in load-bearing structures. In addition, it has excellent high temperature resistance, and can withstand high temperatures of over 2000°C in a non-oxidizing atmosphere.

Application Technology and Process of Ultra-short Carbon Fiber in Aerospace Field

In the aerospace field, ultra-short carbon fiber is mainly used to reinforce resin matrix composites. The key of the technology is to make the carbon fiber evenly dispersed in the resin matrix. For example, adopting ultrasonic dispersion technology can effectively break the phenomenon of carbon fiber agglomeration, so that the dispersion coefficient reaches more than 90%, ensuring the consistency of material properties. At the same time, the use of fiber surface treatment technology, such as the use of coupling agent treatment, can make the carbon fiber and resin interface bond strength increased by 30% – 50%.

In the manufacture of aircraft wings and other structural components, the use of hot pressing tank process. First of all, the ultra-short carbon fiber and resin mixed with a certain proportion made of prepreg, layered into the hot press tank. It is then cured and molded at a temperature of 120 – 180°C and a pressure of 0.5 – 1.5MPa. This process can effectively discharge the air bubbles in the composite material to ensure the denseness and high performance of the products.

Technology and Processes for the Application of Ultra-Short Carbon Fiber in the Automotive Industry

When applying ultra-short carbon fiber to automotive parts, the focus is on improving its compatibility with the base material. By adding specific compatibilizers, the interfacial adhesion between carbon fibers and base materials (e.g. polypropylene, etc.) can be increased by about 40%. At the same time, in order to improve its performance in complex stress environments, fiber orientation design technology is used to adjust the direction of fiber alignment according to the direction of stress on the part.

The injection molding process is often used in the manufacture of parts such as automobile hoods. Ultra-short carbon fibers are mixed with plastic particles and then injected into the mold cavity through high temperature and pressure. The injection temperature is generally 200 – 280 ℃, the injection pressure is 50 – 150 MPa. This process can realize the rapid molding of complex shaped parts, and can ensure the uniform distribution of carbon fibers in the products.

Technology and Process of Ultra-short Carbon Fiber Application in Electronics Field

In the field of electronic heat dissipation, the utilization of thermal conductivity of ultra-short carbon fibers is key. By optimizing the graphitization degree of carbon fiber, its thermal conductivity can be increased to more than 1000W/(m-K). Meanwhile, to ensure its good contact with electronic components, surface metallization technology, such as chemical nickel plating, can reduce the surface resistance of carbon fiber by more than 80%.

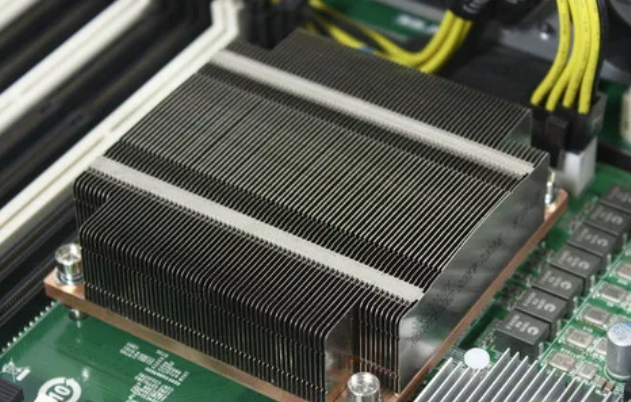

Powder metallurgy process can be used in the manufacture of computer CPU heatsinks. The ultra-short carbon fiber is mixed with metal powder (e.g. copper powder) and sintered under high temperature and pressure. The sintering temperature is generally 500 – 900°C and the pressure is 20 – 50 MPa. This process enables the carbon fiber to form a good heat conduction channel with the metal and improves the heat dissipation efficiency.

From aerospace to automotive industry to electronics, with the continuous innovation of technology and process optimization, ultra-short carbon fiber will shine in more fields, injecting more powerful power for modern science and technology and industrial development.

Post time: Dec-20-2024