Moulding txheej txheem yog ib qho nyiaj ntawm prepreg rau hauv cov hlau pwm kab noj hniav ntawm cov pwm, kev siv cov presses nrog lub tshav kub qhov chaw los tsim ib tug tej yam kub thiab siab kom lub prepreg nyob rau hauv lub pwm kab noj hniav yog softened los ntawm tshav kub, siab txaus, tag nrho cov txaus, puv nrog cov kab noj hniav molding thiab curing khoom ntawm ib tug txheej txheem txheej txheem.

Moulding txheej txheem yog tus cwj pwm los ntawm kev xav tau cua sov hauv cov txheej txheem molding, lub hom phiaj ntawm cov cua sov yog ua kom lub prepreg nyob rau hauv softening ntawm ntws.resin, sau cov pwm kab noj hniav thiab ceev cov tshuaj tiv thaiv kab mob ntawm cov khoom siv matrix resin. Thaum lub sij hawm tus txheej txheem ntawm kev sau cov pwm kab noj hniav nrog prepreg, tsis yog tsuas yog cov resin matrix ntws, tab sis kuj cov ntaub ntawv reinforcing, thiab resin matrix thiab reinforcing fibers sau tag nrho cov seem ntawm cov pwm kab noj hniav tib lub sij hawm.

Tsuas yog covresinmatrix viscosity yog loj heev, daim ntawv cog lus muaj zog heev, thiaj li yuav ntws nrog cov fibers reinforcing, yog li cov txheej txheem molding yuav tsum muaj ntau dua molding siab, uas yuav tsum tau hlau pwm nrog lub zog siab, siab precision thiab corrosion kuj, thiab yuav tsum tau siv tshwj xeeb kub presses los tswj qhov kub ntawm lub curing molding, siab, tuav lub sij hawm thiab lwm yam txheej txheem tsis.

Moulding txoj kev ua haujlwm siab, cov khoom loj qhov tseeb, qhov chaw tiav, tshwj xeeb tshaj yog rau cov qauv ntawm cov khoom siv sib xyaw ua ke feem ntau tuaj yeem raug molded ib zaug, yuav tsis ua rau kev ua haujlwm ntawm cov khoom siv sib xyaw. Nws lub ntsiab tsis txaus yog qhov pwm tsim thiab kev tsim khoom yog qhov nyuaj dua, kev nqis peev thawj zaug loj dua. Txawm hais tias cov txheej txheem molding muaj qhov tsis zoo saum toj no, cov txheej txheem pwm molding tseem muaj txoj haujlwm tseem ceeb hauv cov txheej txheem molding khoom.

1. Kev Npaj

Ua haujlwm zoo ntawmprepreg, molding tooling pwm, nrog rau qhov cub ntsuas qhov kev txhawb nqa kev ua haujlwm, thiab ntxuav cov pwm hauv qhov kawg siv cov residual resin, khib nyiab, kom cov pwm huv si thiab du.

2. Txiav thiab tso prepregs

Yuav ua rau cov khoom ntawm carbon fiber raw cov ntaub ntawv npaj txhij, prepreg tom qab dhau qhov kev tshuaj xyuas, xam thaj tsam ntawm raw cov ntaub ntawv, cov ntaub ntawv, cov ntaub ntawv, cov ntaub ntawv raw txheej los ntawm txheej ntawm xyab ntxiv, nyob rau tib lub sij hawm nyob rau hauv lub superposition ntawm cov khoom rau lub pre-siab, nias rau hauv cov duab ntawm ib tug tsis tu ncua, qhov zoo ntawm ib tug tej yam xov tooj ntawm cov khoom ntom ntom.

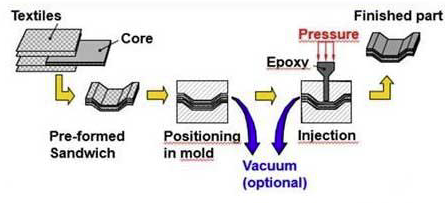

3 、 Pwm thiab kho

Muab cov ntaub ntawv raw khoom tso rau hauv pwm, thiab tib lub sijhawm nyob rau hauv cov hnab yas sab hauv, kaw cov pwm, tag nrho rau hauv lub tshuab molding, cov hnab yas sab hauv ntxiv rau ib qho kev siab tsis tu ncua, qhov kub thiab txias, teem sijhawm tas li, kom nws kho.

4 、 Txias thiab demolding

Tom qab ib lub sij hawm ntawm lub siab sab nraum pwm thawj txias paub rau ib lub sij hawm ntawm lub sij hawm, thiab ces qhib lub pwm, demolding sab nraum lub qhov muag los ntxuav lub tooling pwm.

5 、 Cov txheej txheem molding

Tom qab demolding cov khoom yuav tsum tau muab ntxuav, nrog ib tug txhuam steel los yog tooj liab txhuam kom tshem tawm cov residual yas, thiab tshuab nrog compressed cua, cov khoom molded yog polished, thiaj li hais tias tus nto yog du thiab huv si.

6 、 Kev sim tsis tsim nyog thiab kev tshuaj xyuas zaum kawg

Kev kuaj tsis muaj kev puas tsuaj thiab kev tshuaj xyuas zaum kawg ntawm cov khoom yog ua raws li cov kev xav tau ntawm cov ntaub ntawv tsim.

Kev tshuaj xyuas cov ntsiab lus ntawm cov txheej txheem prepreg molding

Txij li thaum yug los ntawm carbon fiber composites, nws yeej ib txwm raug txwv los ntawm kev tsim cov nqi thiab kev cuam tshuam ntawm cov neeg ntaus khoom, thiab tsis tau siv ntau ntau. Txiav txim siab tus nqi ntawm carbon fiber ntau lawm thiab yeej yog cov txheej txheem molding,carbon fiber composite khoommolding txheej txheem muaj ntau, xws li RTM, VARI, kub xovxwm tso tsheb hlau luam, qhov cub curing prepreg (OOA), thiab lwm yam., tab sis muaj ob lub fwj: 1, lub sij hawm molding voj voog yog ntev; 2, tus nqi yog kim (piv rau hlau thiab yas). Prepreg CompressionMolding, raws li ib yam ntawm cov txheej txheem molding, muaj peev xwm paub batch ntau lawm thiab txo nqi ntau lawm, uas yog ntau thiab ntau lug siv.

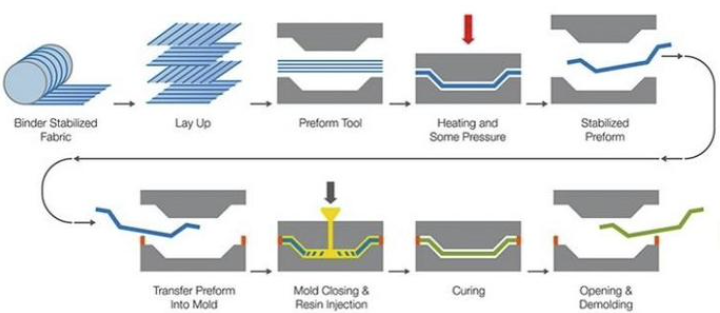

Prepreg molding txheej txheem hais txog qhov kub thiab txias, siab, nyob rau hauv ib lub sij hawm ntawm lub sij hawm yuav prepreg kis mus rau hauv lub pre-zoo li lub cev compression molding. Lub molding ceev ntawm cov txheej txheem no yog ceev, cov khoom yuav tsum tau yooj yim, yooj yim rau kev khiav lag luam, piv nrog cov kub xovxwm tank, VARI thiab OOA txheej txheem, cov khoom yog zoo heev nyob rau hauv ob qho tib si saum npoo pom zoo, zoo seem stability, cov txheej txheem yog yooj yim los tswj.

▲ Pre-preg molding txheej txheem khiav daim ntawv qhia

Plaub yam ntawm cov txheej txheem molding

1. Kub thiab uniformity: qhia txog qib ntawm cov tshuaj tiv thaiv ntawmresinthiabcuring tus neeg sawv cevthiab lub uniformity ntawm cov tshuaj tiv thaiv txoj hauj lwm, mas tswj qhov zoo ntawm molding nto thiab curing degree;

2. Siab thiab uniformity: xav txog cov pa tawm thiab ntws nyhuv hauv cov resin, tswj cov molding nto zoo thiab txhua yam khoom;

3. Qhov ntev ntawm kev kho lub sij hawm: xav txog cov degree ntawm curing, los xyuas kom meej ntau lawm efficiency;

4. Pwm kab noj hniav thickness: xav txog cov tuab ntawm cov khoom, raws li cov yam ntxwv tshwj xeeb ntawm cov khoom siv fiber ntau nws tus kheej, tsim cov kab noj hniav kom tsim nyog.

Cov txheej txheem siv tau

Prepregmolding txheej txheem tuaj yeem theoretically tsim ib qho qauv ntawm cov khoom, cov qauv khoom yog complex, xws li inverted buckle, ntau heev flange cheeb tsam, uas ua rau ib tug ntau ntawm cov nqi ntawm pwm thiab ntau lawm nyuaj, yog li rau cov qauv ntawm tshwj xeeb complex daim ntawv thov tsis muaj zog, tab sis peb yuav ua tau zoo structural optimization los yog block tsim complex kev daws teeb meem.

Related Technology

1. Multi-layer Cutting Technology: Multi-layer prepregs raug txiav ib zaug; prepregs nrog cov ces kaum sib txawv raug txiav ntawm ib lub sij hawm los txhim kho kev txiav.

2. Kub-hauv / kub-tawm tshuab: pwm yog ncaj qha rhuab mus rau qhov kub thiab txias, thiab cov preform yog muab tso rau hauv pwm thiab nias rau hauv cov duab, uas shortens lub sij hawm molding thiab txo lub zog noj.

3. Net-loj molding tshuab: lub preform yog punched rau net-loj ua ntej, thiab ces muab tso rau hauv lub net-loj pwm rau curing, txo cov txheej txheem txiav.

Txheej txheem nyuaj

Kev nyuaj hauv kev tsim pwm rau cov khoom siv cov khoom sib txawv: Yog tias muaj ntau cov buckles inverted thiab cov ces kaum tsis zoo hauv cov khoom, nws yuav ua rau cov pwm nyuaj rau kev tsim khoom, thiab tib lub sijhawm, tom qab cov pwm siv tau ntev, nws yuav ua rau txo qis ntawm qhov kev sib koom ua ke ntawm cov khoom siv. Yog li ntawd, thaum tsim cov khoom, sim zam lub inverted buckle los yog lub kaum sab xis tsis zoo.

Nco tseg: sab nrauv npog qhov chaw ntawm cov khoom saum npoo zoo yuav tsum muaj siab heev, cov khoom siv carbon fiber ntau ntawm cov teeb meem feem ntau yog: cov khoom dew texture qhov chaw dawb; cov teeb meem kev ntxhib los mos ntawm cov khoom; nto pinholes, tsis muaj kua nplaum teeb meem, thiab lwm yam. Txhawm rau suav cov laj thawj, tus neeg sawv cev kho hauv prepreg tsis sib xyaw lossis cov tshuaj tiv thaiv tsis tiav; qhov kub ntawm cov pwm tsis sib xws; qhov kub thiab siab tsis nyob hauv qhov chaw; pwm tsim thiab ua tsis nyob rau hauv qhov chaw; cov txheej txheem molding yog tsis tswj; pwmtso tus neeg sawv cevreacts, thiab lwm yam.

Post lub sij hawm: Jan-17-2025