A zamanin yau na ci gaban fasaha cikin sauri, abubuwan haɗin fiber carbon suna yin suna a fagage daban-daban saboda kyakkyawan aikinsu. Daga manyan aikace-aikace a cikin sararin samaniya zuwa bukatun yau da kullun na kayan wasanni, abubuwan haɗin fiber carbon sun nuna babban yuwuwar. Duk da haka, don shirya high-yi carbon fiber composites, kunnawa jiyya nacarbon fibersmataki ne mai mahimmanci.

Hoton microscope na Carbon fiber surface electron

Fiber Carbon, babban kayan fiber mai aiki, yana da kaddarorin da yawa masu tursasawa. An fi haɗa shi da carbon kuma yana da tsarin filamentary elongated. Daga ra'ayi na tsarin shimfidar wuri, farfajiyar fiber carbon yana da santsi kuma yana da ƙananan ƙungiyoyi masu aiki. Wannan shi ne saboda gaskiyar cewa a lokacin shirye-shiryen na carbon fibers, high-zazzabi carbonization da sauran jiyya sa saman carbon fibers gabatar da wani more inert yanayi. Wannan kayan ƙasa yana kawo jerin ƙalubale ga shirye-shiryen abubuwan haɗin fiber na carbon.

Filaye mai santsi yana sa haɗin gwiwa tsakanin fiber carbon da matrix abu mai rauni. A cikin shirye-shiryen hadaddiyar giyar, yana da wahala ga kayan matrix don samar da haɗin gwiwa mai ƙarfi a kan farfajiyarcarbon fiber, wanda ke shafar aikin gabaɗaya na kayan haɗin gwiwar. Na biyu, rashin ƙungiyoyin aiki masu aiki yana iyakance halayen sinadaran tsakanin fibers carbon da kayan matrix. Wannan yana sanya haɗin kai tsakanin su biyun ya dogara ne akan tasirin jiki, kamar haɗawa da injina, da dai sauransu, wanda galibi ba shi da kwanciyar hankali kuma yana da saurin rabuwa lokacin da aka sa shi ga ƙarfin waje.

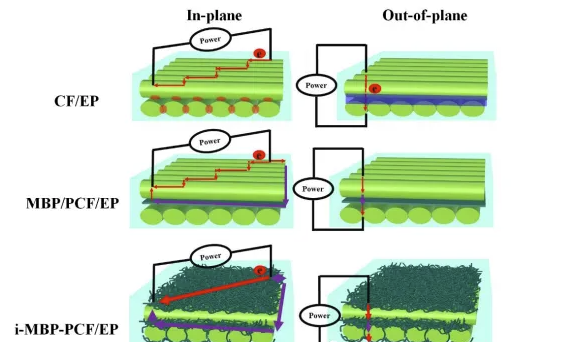

Zane mai tsari na ƙarfafa interlayer na zanen fiber carbon ta carbon nanotubes

Don magance waɗannan matsalolin, kunna jiyya na fiber carbon ya zama dole. Kunnacarbon fibersnuna gagarumin canje-canje a fannoni da dama.

Jiyya na kunnawa yana ƙara ƙarancin filaye na carbon fibers. Ta hanyar oxidation na sinadarai, jiyya na plasma da sauran hanyoyin, ƙananan ramuka da ramuka za a iya shigar da su cikin saman filayen carbon, suna mai da farfajiyar m. Wannan m surface ƙara lamba yankin tsakanin carbon fiber da substrate abu, wanda inganta inji bond tsakanin biyu. Lokacin da matrix abu yana da alaƙa da fiber carbon, zai fi kyau iya shigar da kansa cikin waɗannan ƙaƙƙarfan tsarin, yana samar da haɗin gwiwa mai ƙarfi.

Maganin kunnawa na iya gabatar da ɗimbin ƙungiyoyin aiki masu amsawa akan saman fiber ɗin carbon. Waɗannan ƙungiyoyin masu aiki na iya amsawa ta hanyar sinadarai tare da ƙungiyoyin aiki masu dacewa a cikin kayan matrix don samar da haɗin gwiwar sinadarai. Alal misali, maganin oxidation na iya gabatar da ƙungiyoyin hydroxyl, ƙungiyoyin carboxyl da sauran ƙungiyoyi masu aiki a saman filaye na carbon, wanda zai iya amsawa tare daepoxyƙungiyoyi a cikin matrix guduro da sauransu don samar da haɗin gwiwa. Ƙarfin wannan haɗin gwiwar sinadarai ya fi girma fiye da haɗin kai na jiki, wanda ke inganta ƙarfin haɗin kai tsakanin fiber carbon da kayan matrix.

The surface makamashi na carbon fiber da aka kunna shima yana ƙaruwa sosai. Ƙaruwar makamashin sararin samaniya yana sauƙaƙa don jikar fiber carbon da kayan matrix, don haka sauƙaƙe yadawa da shigar da kayan matrix akan saman fiber na carbon. A cikin aiwatar da shirye-shiryen haɗe-haɗe, kayan matrix za a iya rarraba su daidai a kusa da filayen carbon don samar da tsari mai yawa. Wannan ba kawai inganta kayan aikin injiniya na kayan haɗin gwiwar ba, amma kuma yana inganta sauran kaddarorinsa, kamar juriya na lalata da kwanciyar hankali na thermal.

Kunna filayen carbon da aka kunna suna da fa'idodi da yawa don shirya abubuwan haɗin fiber carbon.

Dangane da kaddarorin inji, ƙarfin haɗin kai tsakanin masu kunnawacarbon fiberskuma kayan matrix yana inganta sosai, wanda ke ba da damar haɗin gwiwar don mafi kyawun canja wurin damuwa lokacin da aka yi wa sojojin waje. Wannan yana nufin cewa kayan aikin injiniyoyi kamar ƙarfi da ma'auni suna haɓaka sosai. Misali, a cikin filin sararin samaniya, wanda ke buƙatar kaddarorin injina masu matuƙar girma, sassan jirgin da aka yi tare da haɗakar fiber carbon da aka kunna suna iya jure babban nauyin jirgin da inganta aminci da amincin jirgin. A fagen kayan wasanni, kamar firam ɗin kekuna, kulake na golf, da dai sauransu, abubuwan haɗin fiber carbon da aka kunna na iya samar da mafi kyawun ƙarfi da taurin kai, tare da rage nauyi da haɓaka ƙwarewar 'yan wasa.

Dangane da juriya na lalata, saboda gabatarwar ƙungiyoyin masu aiki masu amsawa a saman filayen carbon da aka kunna, waɗannan ƙungiyoyin masu aiki na iya samar da ingantaccen haɗin sinadarai tare da kayan matrix, don haka haɓaka juriya na ɓarna. A wasu munanan yanayin muhalli, kamar yanayin ruwa, masana'antar sinadarai, da sauransu, an kunnacarbon fiber compositeszai iya yin tsayayya da zaizayar kafofin watsa labarai masu lalata da kuma tsawaita rayuwar sabis. Wannan yana da mahimmanci ga wasu kayan aiki da tsarin da ake amfani da su a cikin yanayi mai tsanani na dogon lokaci.

Dangane da kwanciyar hankali na thermal, kyakkyawar haɗin kai tsakanin fiber carbon da aka kunna da kayan matrix na iya haɓaka kwanciyar hankali na thermal composites. Ƙarƙashin yanayin zafi mai girma, abubuwan da aka haɗa zasu iya kula da ingantattun kaddarorin inji da kwanciyar hankali mai girma, kuma ba su da saurin lalacewa da lalacewa. Wannan ya sa abubuwan haɗin fiber carbon da aka kunna suna da fa'idodin aikace-aikacen aikace-aikacen a cikin aikace-aikacen zafin jiki mai ƙarfi, kamar sassan injin mota da sassan ƙarshen injin jirgin sama.

Dangane da aikin sarrafawa, filayen carbon da aka kunna sun ƙara yawan aikin saman da mafi dacewa da kayan matrix. Wannan yana ba da sauƙi ga kayan matrix don kutsawa da warkarwa a saman fiber na carbon yayin shirye-shiryen kayan haɗin gwiwar, don haka inganta ingantaccen aiki da ingancin samfur. A lokaci guda kuma, ana haɓaka ƙirar abubuwan haɗin fiber carbon da aka kunna, yana ba su damar daidaita su don aikace-aikacen daban-daban da kuma biyan buƙatun injiniyoyi daban-daban.

Saboda haka, kunnawa jiyya nacarbon fibersshine maɓalli mai mahimmanci a cikin shirye-shiryen manyan abubuwan haɗin gwiwar carbon fiber composites. Ta hanyar kunnawa jiyya, da surface tsarin na carbon fiber za a iya inganta don ƙara da surface roughness, gabatar da aiki kungiyoyin, da kuma inganta surface makamashi, don inganta interfacial bonding ƙarfi tsakanin carbon fiber da matrix abu, da kuma aza harsashi ga shiri na carbon fiber composites tare da m inji Properties, lalata juriya, thermal kwanciyar hankali da kuma aiki yi. Tare da ci gaba da ci gaban kimiyya da fasaha, an yi imanin cewa fasahar kunna fiber carbon za ta ci gaba da haɓakawa da haɓakawa, samar da goyon baya mai karfi ga aikace-aikacen da aka haɗa da fiber carbon.

Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368 (kuma whatsapp)

T:+86 08383990499

Email: grahamjin@jhcomposites.com

Adireshi: NO.398 Sabuwar Koren Titin Xinbang Garin Songjiang, Shanghai

Lokacin aikawa: Satumba-04-2024