Me zai faru idan za a iya haɗa abubuwan haɗin fiber na fiber na polymer (GFRP) a ƙarshen rayuwarsu mai amfani, ban da shekarun da suka gabata na fa'idodin da aka tabbatar na rage nauyi, ƙarfi da taurin kai, juriya da karko? Wannan, a taƙaice, shine roƙon fasahar ABM Composite.

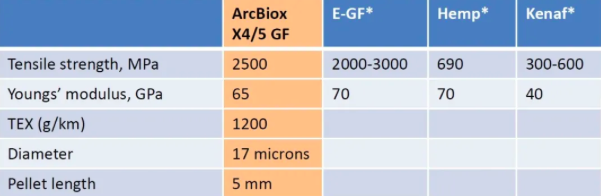

Gilashin Bioactive, babban ƙarfin zaruruwa

An kafa shi a cikin 2014, Arctic Biomaterials Oy (Tampere, Finland) ya haɓaka fiber na gilashin da ba za a iya canza shi ba daga abin da ake kira gilashin bioactive, wanda Ari Rosling, darektan R&D a ABM Composite, ya bayyana a matsayin "wani tsari na musamman da aka haɓaka a cikin 1960s wanda ke ba da damar gilashin ya zama ƙasƙanci a ƙarƙashin yanayin yanayin sodium, lokacin da aka gabatar da shi a cikin gishiri mai narkewa a cikin jiki. magnesium, phosphates, da dai sauransu, don haka haifar da yanayin da ke motsa ƙashi girma."

“Yana da kaddarorin kamaFiber gilashin alkali (E-glass).” Rosling ya ce, "Amma wannan gilashin da ke aiki yana da wuyar ƙirƙira da kuma jawo shi cikin zaruruwa, kuma har ya zuwa yanzu ana amfani da shi azaman foda ne kawai. Kamar yadda muka sani, ABM Composite shine kamfani na farko da ya fara samar da filaye masu ƙarfi daga gare ta akan sikelin masana'antu, kuma yanzu muna amfani da waɗannan filayen gilashin ArcBiox X4/5 don ƙarfafa nau'ikan robobi daban-daban, gami da polymers masu haɓakawa.

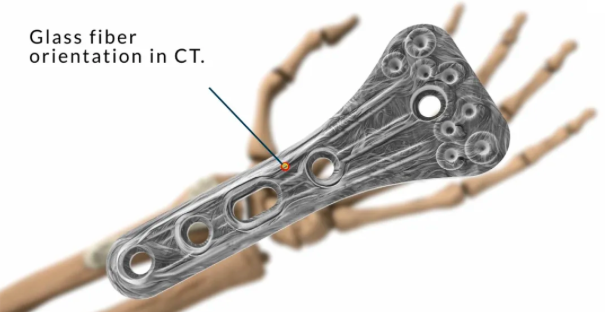

Magungunan dasa shuki

Yankin Tampere, sa'o'i biyu a arewa da Helsinki, Finland, ya kasance cibiya ce ta polymers masu lalata halittu don aikace-aikacen likita tun daga 1980's. Rosling ya bayyana cewa, "Daya daga cikin na'urorin da aka fara samu na kasuwanci da aka yi da waɗannan kayan an samar da su a Tampere, kuma ta haka ne ABM Composite ya fara!

"Akwai da yawa biodegradable, bioabsorbable polymers ga implants." Ya ci gaba da cewa, "amma kayan aikinsu sun yi nisa da kashi na halitta. Mun sami damar haɓaka waɗannan polymers ɗin da za su iya ba da ƙarfi don ba da ƙarfi iri ɗaya kamar kashi na halitta". Rosling ya lura cewa filayen gilashin ArcBiox na likitanci tare da ƙari na ABM na iya haɓaka kaddarorin injiniyoyi na PLLA polymers ta hanyar 200% zuwa 500%.

A sakamakon haka, abubuwan da aka sanya na ABM Composite suna ba da aiki mafi girma fiye da na'urorin da aka yi da polymers marasa ƙarfi, yayin da suke zama masu iya rayuwa da inganta haɓakar kashi da girma. ABM Composite kuma yana amfani da dabarun sanya fiber/maɓalli mai sarrafa kansa don tabbatar da ingantacciyar daidaitawar fiber, gami da ɗorawa zaruruwa tsawon tsayin daka, da kuma sanya ƙarin zaruruwa a wurare masu rauni.

Aikace-aikacen gida da fasaha

Tare da haɓakar sashin kasuwancinta na likitanci, ABM Composite ya gane cewa ana iya amfani da polymers na tushen halittu da kuma abubuwan da ba za a iya lalata su ba don kayan dafa abinci, kayan abinci da sauran kayan gida. "Waɗannan polymers ɗin da za su iya rayuwa galibi suna da ƙarancin kayan aikin injiniya idan aka kwatanta da robobin tushen man fetur." Rosling ya ce, "Amma za mu iya ƙarfafa waɗannan kayan tare da filayen gilashin da za a iya lalata su, yana mai da su kusan kyakkyawan madadin robobin kasuwanci na tushen burbushin don aikace-aikacen fasaha da yawa".

Sakamakon haka, ABM Composite ya haɓaka sashin kasuwancin fasaha, wanda yanzu ke ɗaukar mutane 60. "Muna ba da ƙarin mafita mai dorewa na ƙarshen rayuwa (EOL)." Rosling ya ce, "Shawarar darajarmu ita ce sanya waɗannan abubuwan da za su iya lalacewa cikin ayyukan takin masana'antu inda suka zama ƙasa." Gilashin E-gilashin na gargajiya ba shi da aiki kuma ba zai ƙasƙanta ba a cikin waɗannan wuraren takin.

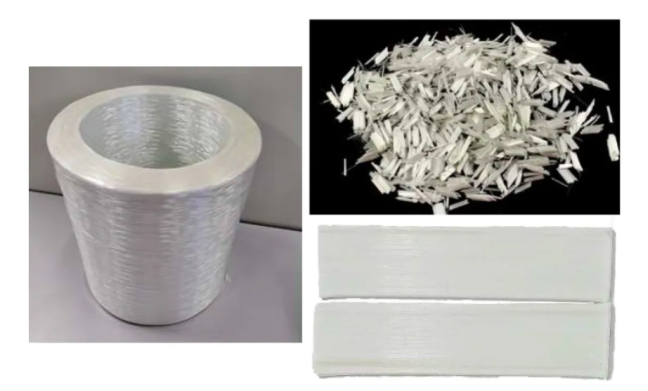

ArcBiox Fiber Composites

ABM Composite ya ɓullo da nau'o'i daban-daban na ArcBiox X4/5 gilashin fibers don aikace-aikace masu haɗaka, dagagajerun zaruruwada allura gyare-gyaren mahadi zuwaci gaba da zaruruwadon matakai irin su yadi da gyare-gyaren pultrusion. ArcBiox BSGF kewayon ya haɗu da filayen gilashin biodegradable tare da resins na tushen polyester kuma ana samun su a cikin makin fasaha na gabaɗaya da maki ArcBiox 5 waɗanda aka amince don amfani da aikace-aikacen tuntuɓar abinci.

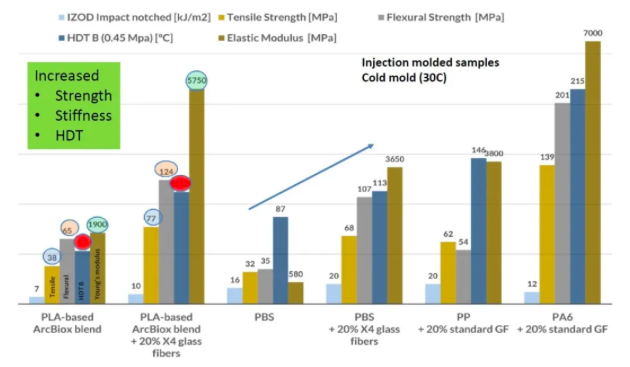

ABM Composite ya kuma binciki nau'ikan nau'ikan nau'ikan nau'ikan kwayoyin halitta da na tushen halittu ciki har da Polylactic Acid (PLA), PLLA da Polybutylene Succinate (PBS). Hoton da ke ƙasa yana nuna yadda filayen gilashin X4/5 zasu iya inganta aikin don yin gasa tare da madaidaicin fiber gilashin da aka ƙarfafa polymers kamar polypropylene (PP) har ma da polyamide 6 (PA6).

Har ila yau, ABM Composite ya bincika nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan kwayoyin halitta da na tushen halittu, gami da Polylactic Acid (PLA), PLLA da Polybutylene Succinate (PBS). Hoton da ke ƙasa yana nuna yadda filayen gilashin X4/5 zasu iya inganta aikin don yin gasa tare da madaidaicin fiber gilashin da aka ƙarfafa polymers kamar polypropylene (PP) har ma da polyamide 6 (PA6).

Dorewa & Taki

Idan waɗannan haɗe-haɗe suna da lalacewa, har yaushe za su dawwama? "Filayen gilashin mu na X4/5 ba sa narkewa a cikin mintuna biyar ko na dare kamar sukari, kuma yayin da kaddarorin su za su lalace kan lokaci, ba za a iya gani ba." Rosling ya ce, "Don ƙasƙanta yadda ya kamata, muna buƙatar yanayin zafi da zafi na dogon lokaci, kamar yadda ake samu a vivo ko a cikin takin masana'antu. Misali, mun gwada kofuna da kwano da aka yi daga kayan ArcBiox BSGF ɗinmu, kuma za su iya jure wa zagayowar wanki 200 ba tare da rasa aiki ba. amfani".

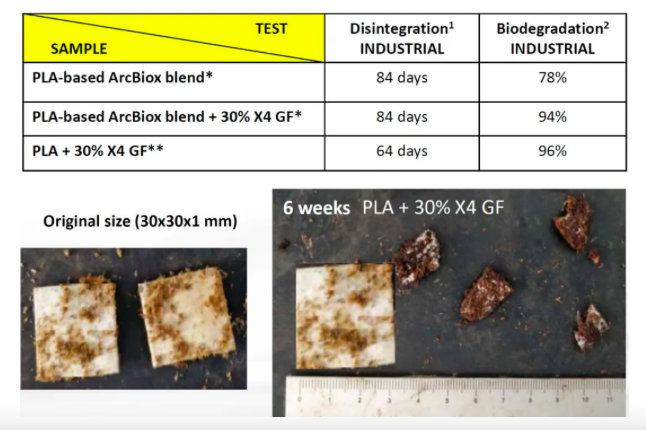

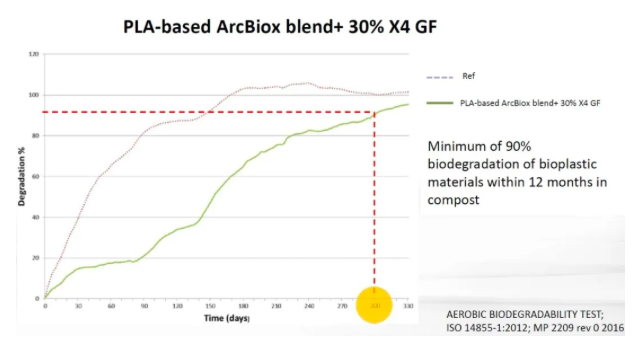

Duk da haka, yana da mahimmanci idan aka zubar da waɗannan abubuwan haɗin gwiwar a ƙarshen rayuwarsu, sun cika ka'idodin da ake buƙata don takin, kuma ABM Composite ya yi jerin gwaje-gwaje don tabbatar da cewa ya cika waɗannan ka'idoji. "Bisa ga ka'idodin ISO (don takin masana'antu), biodegradation ya kamata ya faru a cikin watanni 6 kuma bazuwar cikin watanni 3/90". Rosling ya ce, "Rushewa yana nufin sanya samfurin gwajin / samfurin a cikin biomass ko takin. bayan kwanaki 90, mai fasaha yana nazarin biomass ta amfani da sieve. bayan makonni 12, akalla kashi 90 na samfurin ya kamata ya wuce ta hanyar 2 mm × 2 mm sieve".

Ana ƙayyade ƙwayar cuta ta hanyar niƙa kayan budurwa a cikin foda da auna yawan adadin CO2 da aka saki bayan kwanaki 90. Wannan yana kimanta yawan adadin carbon na tsarin takin da aka canza zuwa ruwa, biomass da CO2. "Don cin nasarar gwajin takin masana'antu, 90 bisa dari na ka'idar 100% CO2 daga tsarin takin dole ne a cimma (dangane da abun ciki na carbon)".

Rosling ya ce ABM Composite ya cika buƙatun ɓarna da ƙayyadaddun halittu, kuma gwaje-gwaje sun nuna cewa ƙari na gilashin gilashin sa na X4 yana inganta haɓakar halittu (duba tebur a sama), wanda shine kawai 78% don haɗakar PLA mara ƙarfi, alal misali. Ya yi bayanin, "Duk da haka, lokacin da aka ƙara 30% na filayen gilashin biodegradable, ɓacin rai ya karu zuwa 94%, yayin da ƙimar lalacewa ta kasance mai kyau".

A sakamakon haka, ABM Composite ya nuna cewa kayan sa za a iya ba da takardar shaida a matsayin takin zamani bisa ga EN 13432. Gwaje-gwajen da kayan sa suka wuce har zuwa yau sun haɗa da ISO 14855-1 don ƙarshen aerobic biodegradaability na kayan a ƙarƙashin yanayin sarrafa takin, ISO 16929 don bazuwar iska mai sarrafa iska, ISO DIN EN 2EC don buƙatun sinadarai, ISO DIN 2EC don buƙatun sinadarai, 1340 TS EN 13432 Gwajin phytotoxicity

CO2 da aka saki yayin takin

Lokacin da ake yin takin, CO2 yana fitowa, amma wasu sun kasance a cikin ƙasa sannan tsire-tsire suna amfani da su. An yi nazarin takin zamani shekaru da yawa, duka a matsayin tsarin masana'antu da kuma tsarin bayan-taki wanda ke fitar da ƙasa da CO2 fiye da sauran hanyoyin zubar da shara, kuma har yanzu ana ɗaukar takin a matsayin mai kyautata muhalli da rage sawun carbon.

Ecotoxicity ya haɗa da gwada kwayoyin halitta da aka samar yayin aikin takin da kuma tsire-tsire da aka girma tare da wannan kwayoyin halitta. "Wannan shine don tabbatar da cewa takin waɗannan samfuran baya cutar da tsire-tsire masu girma." Rosling ya ce. Bugu da kari, ABM Composite ya nuna cewa kayan sa sun cika buƙatun ɓacin rai a ƙarƙashin yanayin takin gida, wanda kuma yana buƙatar 90% biodegradation, amma a cikin watanni 12, idan aka kwatanta da ɗan gajeren lokaci don takin masana'antu.

Aikace-aikacen masana'antu, samarwa, farashi da haɓaka gaba

Ana amfani da kayan ABM Composite a aikace-aikacen kasuwanci da yawa, amma ƙarin ba za a iya bayyana su ba saboda yarjejeniyar sirri. "Muna yin odar kayan mu don dacewa da aikace-aikace kamar kofuna, saucers, faranti, cutlery da kwantenan ajiyar abinci," in ji Rosling, "amma kuma ana amfani da su azaman madadin robobi na tushen man fetur a cikin kwantena na kwaskwarima da manyan kayan gida. Kwanan nan, an zaɓi kayan mu don amfani da kayan aikin da aka gyara a cikin manyan kayan aikin masana'antu da ke buƙatar maye gurbinsu ta hanyar amfani da waɗannan nau'o'in 2-12 na gilashin fiber, wanda za a iya gane su a kowane mako na 2-12. a yi tare da juriya da ake buƙata kuma ana iya yin takin bayan amfani.

Rosling ya kara da cewa, "Har ila yau, akwai karuwar sha'awar yin amfani da fibers ɗinmu na ci gaba a cikin nau'ikan yadudduka daban-daban da na'urorin da ba a saka ba don yin kayan gini don masana'antar gine-gine.

A halin yanzu, X4 / 5 fiberglass ya fi tsada fiye da E-glass, amma adadin samar da ƙananan ƙananan ƙananan ƙananan, kuma ABM Composite yana neman dama da dama don fadada aikace-aikace da kuma sauƙaƙe haɓakawa har zuwa tan 20,000 / shekara yayin da bukatar girma, wanda kuma zai iya taimakawa wajen rage farashin. Ko da haka, Rosling ya ce a yawancin lokuta ba a yi la'akari da ƙimar kuɗin da ke tattare da biyan dorewa da sabbin ka'idoji ba. A halin yanzu, gaggawa na ceton duniya yana girma. "Al'umma sun riga sun matsa don samun ƙarin samfuran tushen halittu." Ya bayyana cewa, "Akwai abubuwan karfafawa da yawa don ciyar da fasahohin sake yin amfani da su a gaba, duniya na bukatar ci gaba da sauri a kan wannan kuma ina tsammanin al'umma za ta kara yawan yunƙurinta na samfurori na zamani a nan gaba".

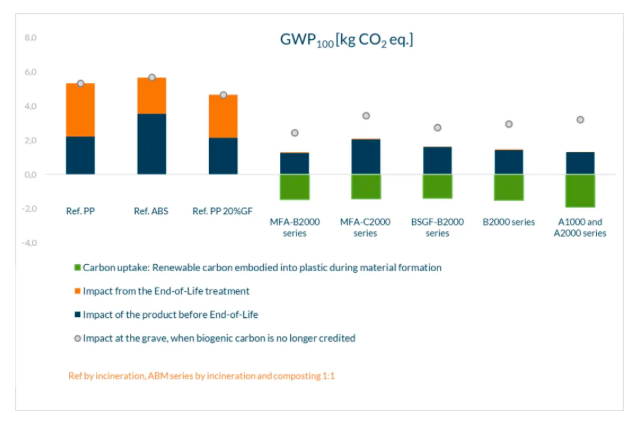

LCA da Amfanin Dorewa

Rosling ya ce kayan ABM Composite na rage fitar da hayaki mai gurbata muhalli da kuma amfani da makamashin da ba a iya sabuntawa da kashi 50-60 cikin 100 na kilogiram. "Muna amfani da Database na Sawun Muhalli 2.0, bayanan GaBi da aka amince da su, da LCA (Life Cycle Analysis) don samfuranmu bisa tsarin da aka tsara a cikin ISO 14040 da ISO 14044"

"A halin yanzu, lokacin da abubuwan da aka haɗa suka kai ƙarshen tsarin rayuwarsu, ana buƙatar makamashi mai yawa don ƙonewa ko pyrolyse sharar gida da kayayyakin EOL, kuma shredding da takin zamani zaɓi ne mai ban sha'awa, kuma tabbas yana ɗaya daga cikin mahimman abubuwan ƙima da muke bayarwa, kuma muna samar da sabon nau'in sake yin fa'ida." Rosling ya ce, "Fiberglass ɗinmu an yi shi ne daga abubuwan ma'adinai na halitta waɗanda suka riga sun kasance a cikin ƙasa. Don haka me yasa ba za a takin kayan haɗin EOL ba, ko kuma a narkar da fibers daga abubuwan da ba za a iya lalacewa ba bayan an ƙone su kuma a yi amfani da su azaman taki? Wannan zaɓi ne na sake yin amfani da shi na ainihin sha'awar duniya. "

Shanghai Orisen New Material Technology Co., Ltd

M: +86 18683776368 (kuma WhatsApp)

T:+86 08383990499

Email: grahamjin@jhcomposites.com

Adireshi: NO.398 Sabuwar Titin Koren Xinbang Garin Songjiang, Shanghai

Lokacin aikawa: Mayu-27-2024