A matsayin babban memba na ci-gaba filin haɗe-haɗe, ultra-short carbon fiber, tare da keɓaɓɓen kaddarorin sa, ya jawo hankalin tartsatsi a yawancin masana'antu da fasaha. Yana ba da sabon sabon bayani don babban aikin kayan aiki, kuma zurfin fahimtar fasahar aikace-aikacen sa da matakai yana da mahimmanci don haɓaka haɓakar masana'antu masu alaƙa.

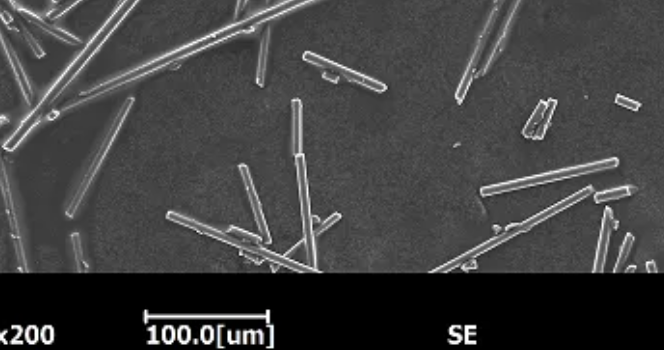

Electron micrographs na ultrashort carbon fibers

Yawanci, tsayin filayen carbon gajere yana tsakanin 0.1 – 5mm, kuma yawansu ya ragu a 1.7 – 2g/cm³. Tare da ƙananan ƙarancin 1.7 - 2.2g / cm³, ƙarfin ƙarfi na 3000 - 7000MPa da elasticity na 200 - 700GPa, waɗannan kyawawan kaddarorin inji sun zama tushen don amfani dashi a cikin sifofin ɗaukar nauyi. Bugu da ƙari, yana da kyakkyawan juriya na zafin jiki, kuma yana iya jure yanayin zafi sama da 2000 ° C a cikin yanayi mara kyau.

Fasahar Aikace-aikace da Tsarin Carbon Fiber mai ɗan gajeren gajere a Filin Jirgin Sama

A cikin filin sararin sama, ultra-short carbon fiber ana amfani dashi don ƙarfafawaguduromatrix composites. Makullin fasaha shine sanya fiber carbon a ko'ina ya tarwatse a cikin matrix resin. Alal misali, ɗaukar fasahar watsawa na ultrasonic na iya yadda ya kamata ya karya abin da ke faruwa na carbon fiber agglomeration, wanda ya sa yawan adadin watsawa ya kai fiye da 90%, yana tabbatar da daidaiton kayan kaddarorin. A lokaci guda, yin amfani da fasahar jiyya na fiber surface, kamar amfani dawakilin hada biyumagani, zai iya sacarbon fiberkuma ƙarfin haɗin haɗin gwiwar guduro ya ƙaru da 30% - 50%.

A cikin kera fuka-fukan jirgin sama da sauran abubuwan da aka gyara, yin amfani da tsarin tanki mai zafi. Da farko, ultra-short carbon fiber da guduro gauraye da wani rabo sanya na prepreg, layered cikin zafi latsa tank. Sannan ana warkewa ana yin shi a zafin jiki na 120 - 180 ° C da matsa lamba na 0.5 - 1.5MPa. Wannan tsari na iya fitar da kumfa mai inganci yadda ya kamata a cikin kayan hade don tabbatar da yawa da babban aikin samfuran.

Fasaha da Tsari don Aikace-aikacen Fiber Carbon Short Short a cikin Masana'antar Motoci

Lokacin amfani da ultra-short fiber fiber carbon zuwa sassa na kera, ana mai da hankali kan inganta dacewarsa da kayan tushe. Ta ƙara takamaiman masu daidaitawa, mannewar fuska tsakanin filayen carbon da kayan tushe (misalipolypropylene, da dai sauransu) za a iya ƙara da kusan 40%. A lokaci guda kuma, don inganta aikinta a cikin mawuyacin yanayi mai rikitarwa, ana amfani da fasahar ƙirar fiber daidaitawa don daidaita yanayin daidaitawar fiber bisa ga yanayin damuwa a ɓangaren.

Ana amfani da tsarin gyare-gyaren allura sau da yawa wajen kera sassa kamar hulun mota. Ana gaurayawan filayen carbon gajere da ƙananan ƙwayoyin robobi sannan a yi musu allura a cikin kogon ƙura ta hanyar zafin jiki da matsa lamba. The allura zafin jiki ne kullum 200 - 280 ℃, da allura matsa lamba ne 50 - 150 MPa. Wannan tsari na iya gane saurin gyare-gyaren sassa masu siffa mai rikitarwa, kuma yana iya tabbatar da daidaitaccen rarraba filayen carbon a cikin samfuran.

Fasaha da Tsarin Aikace-aikacen Fiber Carbon Short Short a Filin Lantarki

A fagen watsar da zafi na lantarki, yin amfani da ƙarancin zafin jiki na filayen carbon gajere shine maɓalli. Ta hanyar inganta matakin graphitization na fiber carbon, ana iya ƙara ƙarfin ƙarfin zafin sa zuwa fiye da 1000W/(mK). A halin yanzu, don tabbatar da kyakkyawar hulɗa tare da kayan aikin lantarki, fasaha na ƙarfe na ƙarfe, irin su sinadarai nickel plating, na iya rage juriya na fiber carbon fiye da 80%.

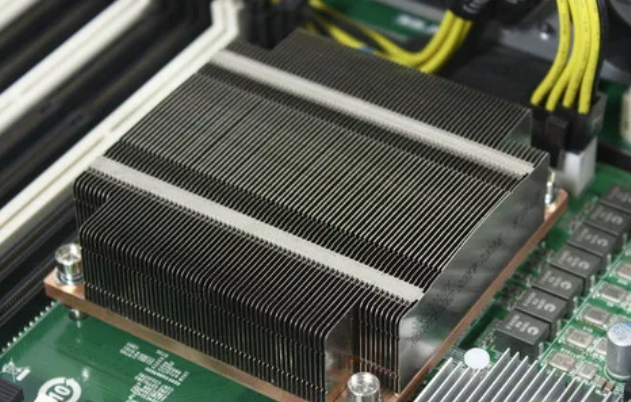

Ana iya amfani da tsarin ƙarfe na foda wajen kera heatsinks na CPU na kwamfuta. A matsananci-short carbon fiber ne gauraye da karfe foda (misali jan karfe foda) da kuma sintered karkashin high zafin jiki da kuma matsa lamba. Matsakaicin zafin jiki gabaɗaya shine 500 - 900 ° C kuma matsa lamba shine 20 - 50 MPa. Wannan tsari yana ba da fiber carbon don samar da tashar tashar zafi mai kyau tare da karfe kuma yana inganta haɓakar zafi.

Daga sararin samaniya zuwa masana'antar kera motoci zuwa na'urorin lantarki, tare da ci gaba da haɓaka fasahar fasaha da haɓaka tsari, gajeriyar gajeriyar hanya.carbon fiberza su haskaka a fagage da yawa, tare da yin allura mai ƙarfi don kimiyya da fasaha na zamani da ci gaban masana'antu.

Lokacin aikawa: Dec-20-2024