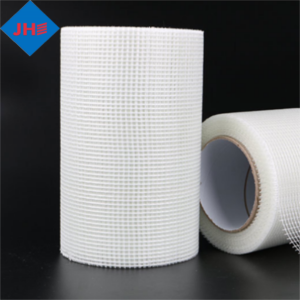

Factory made hot-sale Fiber Glass 386t/H E-Glass Direct Roving 735tex 2200/8800tex for Sectional Bars

We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for Factory made hot-sale Fiber Glass 386t/H E-Glass Direct Roving 735tex 2200/8800tex for Sectional Bars, Our corporation maintains risk-free enterprise combined by truth and honesty to maintain long-term interactions with our clients.

We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for China Fiberglass Roving and Multi End Roving, We now have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

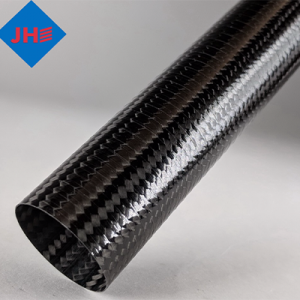

It is widely used in multi-axial fabrics, Polypropylene, Filament winding,LFT-D, Optical Cable for Pultrusion.

Fiberglass direct roving’s feature is good apical and fatigue properties,good in epoxide resin system,specially silane-based sizing and better resin penetration effect.

It is should be stored in cool and dry area .Recommended temperature range is around 10-30℃, and humidity shoulder be 35-65%. Be sure to protect the product from the weather and other sources of water.

The glass fiber products must remain in their original packaging material until the point of usage.

|

Fiber glass type |

Fiberglass diameter(um) |

Roving Density(tex) |

Fiberglass Filament Tensile Strength (GPa)

|

Fiberglass Filament Tensile Modulus(GPa) |

Stiffness(mm) |

|

E-glass |

14 for 300 and 600tex 16/17 for 900 and 1200tex17/22for2400tex |

600-2400 |

≥0.4N/Tex |

>70 |

120±10 |

Each bobbin is wrapped by a PVC shrink bag. If required, each bobbin could be packed into a suitable cardboard box. Each pallet contains 3 or 4 layers, and each layers contain 16 bobbins (4*4). Each 20ft container normally loads 10 small pallets (3layers) and 10 big pallets (4 layers). The bobbins in the pallet could be singly piled or be connected as start to end by air spliced or by manual knots;

Delivery: 3-30days after order.

Unless otherwise specified, the fiberglass products should be stored in a dry, cool and moisture proof area. Best used within 12 months after production date. They should remain in their original packaging until just prior to use. The products are suitable for delivery by the way of ship, train, or truck.